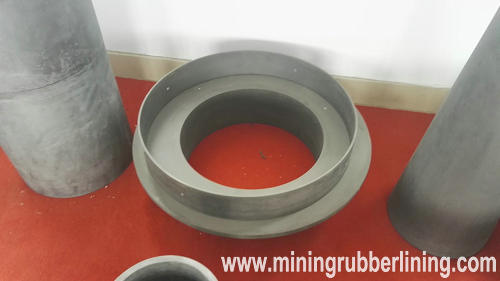

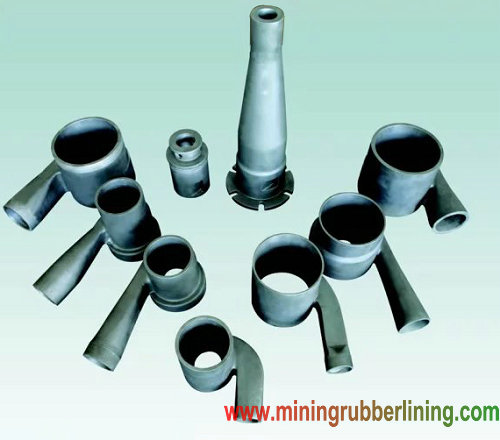

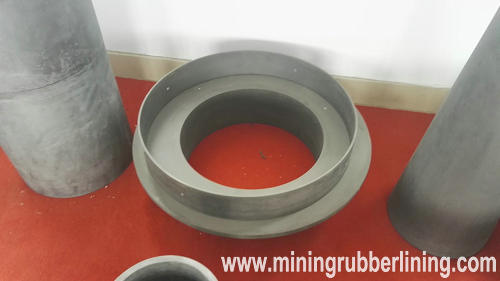

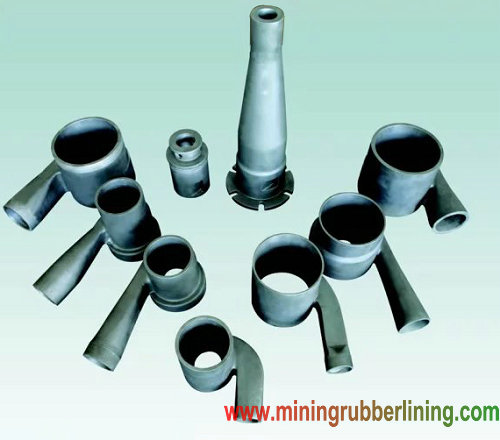

Silicon Carbide Linings | Silicon Carbide Hydrocyclone Liner | SIC Ceramic Cyclone Parts

Detailed Silicon Carbide Hydrocyclone Linings Parameters:

1, Material: Reaction Sintered Silicon Carbide Ceramics;

2, Operating Temperature :≤1380℃;

3, Products: Quick Cold And Heat Resistance, Acid Resistance, Alkali Resistance, High Hardness, Oxidation Resistance, High Strength, No Slag, No Cracking, Long Service Life;

Advantages Of Silicon Carbide Linings

1, Wear Resistance

Wear Resistant Silicon Carbide Ceramic Morse Hardness Up To 13, Equivalent To More Than Hrc90 . Therefore, It Has High Wear Resistance To Grinding Media Treated In Metallurgy, Electric Power, Mining, Coal And Other Industries . It Is Confirmed By Industrial Operation That Its Wear-Resistant Life Is Ten Times Or Even Dozens Times That Of Quenched Steel .

2, Running Resistance Is Small

The Silicon Carbide Wear-Resistant Ceramics Are Smooth And Never Rusted On The Inner Surface, And Are Not Like The Convex Spiral Line On The Inner Surface Of Seamless Steel Skeleton . The Inner Surface Smoothness Is Better Than Any Metal, And The Clear Resistance Coefficient Is 0 .0193, Which Is Slightly Lower Than That Of Seamless Skeleton .

3, Corrosion Resistance, Anti-Scaling

Since The Ceramic Linings Is Silicon Carbide Ceramic ( SiSIC ), It Is Of Neutral Character . Therefore, It Has The Characteristics Of Acid And Alkali Resistance And Seawater Corrosion Resistance, As Well As Anti-Scaling And So On .

4, Good Temperature Resistance And Heat Resistant Punching Property

As This Silicon Carbide Ceramic ( SiSIC ) Is a Single Stable Crystalline Structure . Hence The Composite Skeleton Can Operate Normally For a Long Time In The Temperature Range ℃-50--1380 . The Material Line Expansion Coefficient 6-8×10-6/0 C, Is About 1/2 Of Steel Material .

5, Project Cost Low

Silicon Carbide Wear-Resistant Ceramics Are Light In Weight And Suitable In Price . 50% Lighter Than The Cast Stone Skeleton With The Same Inner Diameter ;20-30% Lighter Than The Wear Resistant Alloy Skeleton .

6, Easy Installation And Construction

Due To The Light Weight Of Silicon Carbide Wear-Resistant Ceramics And Good Welding Performance . Construction And Installation Is Convenient .

7, Silicon Carbide Wear-Resistant Ceramics And Traditional Cyclone, Wear-Resistant Alloy Casting Cyclone, Cast Stone Cyclone, As Well As Steel Plastic Cyclone, Steel Rubber Cyclone And So On Have Essential Differences . The Outer Layer Of Ceramic Steel Skeleton Is Steel Skeleton, And The Inner Layer Is Corundum . Silicon Carbide Wear-Resistant Ceramic Vickers Hardness Up To 2500( Rock Hardness 120-250 ), Equivalent To Tungsten Cobalt Hard Gold .

8, The Wear Resistance Is More Than 40 Times Higher Than That Of Carbon Steel, Which Is Much Better Than The Corundum Grinding Wheel, Which Is Usually Bonded . Now The Steel And Jade Grinding Wheel Is Still The Main Grinding Wheel Of Various Grinding Machines . The Corundum Layer In The Ceramic Cyclone Can Wear Out The Corundum Grinding Wheel . The Wear Resistance Of Ceramic Hydrocyclone Mainly Depends On The Corundum Layer With a Thickness Of a Few Millimeters In The Inner Layer, And Its Morn Hardness Is 13, Second Only To Diamond And Silicon Carbide, And Its Hardness Is The Highest Among All Oxides .