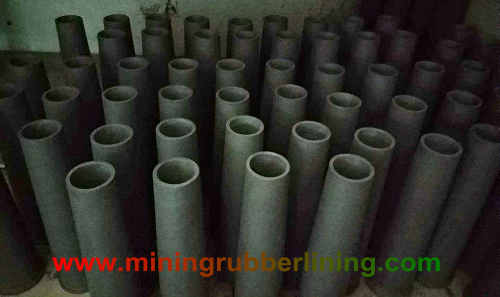

Silicon Carbide Pipe As Name As SIC Ceramic Tube . It Is Very Popular In The Market Because Of Its High Temperature Resistance, Corrosion Resistance And Wear Resistance.

Silicon Carbide Pipe Characteristic

1. Good Wear Resistance

Silicon Carbide Pipe Is Made Of Silicon Carbide Ceramic (Sisic), And Its Mohs Hardness Can Reach 13, Which Is Equivalent To Over Hrc90. Therefore, It Has High Wear Resistance To The Abrasive Media Transported By Metallurgy, Electric Power, Mining, Coal And Other Industries. It Has Been Proved By Industrial Operation That Its Wear Resistance Life Is Ten Times Or Even Dozens Of Times That Of Quenched Steel.

2. Low Running Resistance

Silicon Carbide Pipe Is Smooth And Never Rusted On The Inner Surface, And Does Not Exist As Convex Helix On The Inner Surface Of Seamless Steel Pipe. The Internal Surface Roughness And Water Resistance Characteristics Of The Pipeline Are Tested By The Relevant Testing Units. The Internal Surface Smoothness Is Better Than That Of Any Metal Pipeline, And The Clearance Resistance Coefficient Is 0.0193, Slightly Lower Than That Of Seamless Pipeline.

3. Corrosion And Scale Resistance

As The Steel Ceramic Layer Is Sisic, It Is Neutral. Therefore, It Has The Characteristics Of Acid And Alkali Resistance, Seawater Corrosion Resistance And Scale Resistance.

4. Good Temperature Resistance And Impact Resistance

The Sic Ceramic (Sisic) Is a Single Stable Crystal Structure. Therefore, The Composite Tube Can Operate Normally For a Long Time In The Temperature Range Of - 50-1380 ℃. The Linear Expansion Coefficient Of The Material Is 6-8 × 10-6 / 0C, About 1 / 2 Of The Steel Pipe.

5. Low Project Cost

The Silicon Carbide Pipe Is Light And Affordable. It Is 50% Lighter Than The Cast Stone Pipe With The Same Inner Diameter And 20-30% Lighter Than The Wear-Resistant Alloy Pipe.

6. Convenient Installation And Construction

Because Silicon Carbide Pipe Is Light In Weight And Has Good Welding Performance. Therefore, Welding, Flange, Quick Connection And Other Methods Can Be Adopted, Which Is Convenient For Construction And Installation.

7. Silicon Carbide Pipe Is Essentially Different From Traditional Steel Pipe, Wear-Resistant Alloy Cast Steel Pipe, Cast Stone Pipe, Steel Plastic Pipe And Steel Rubber Pipe. The Outer Layer Of Ceramic Steel Pipe Is Steel Pipe And The Inner Layer Is Corundum. The Vickers Hardness Of Silicon Carbide Pipe Is Up To 2500 (Rockwell Hardness Is 120-250), Which Is Equivalent To Tungsten Cobalt Hard Gold. The Wear Resistance Is More Than 40 Times Higher Than That Of Carbon Steel Pipe, Which Is Much Better Than That Of Corundum Wheel. At Present, Corundum Wheel Is Still The Main Grinding Wheel For Grinding Hardened Steel. The Corundum Layer In The Ceramic Steel Pipe Can Wear Away The Corundum Grinding Wheel. The Wear Resistance Of Ceramic Steel Pipe Mainly Depends On The Corundum Layer With a Thickness Of Several Millimeters. Its Mohs Hardness Is 13, Next To Diamond And Silicon Carbide. Among All Oxides, Its Hardness Is The Highest.

As Long As The Technological Process Of Silicon Carbide Grinding Barrel Is Firmly Controlled, Then The Products Produced Are Naturally Superior!

Contact: Sales Department

Phone: +86 138 10365943

Tel: +86 166 33372827

Email: sales@miningrubberlining.com

Add: No.910 Zhongshan West Road Qiaoxi District Shijiazhuang Hebei China