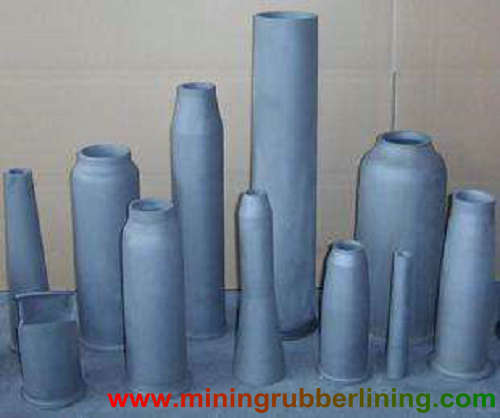

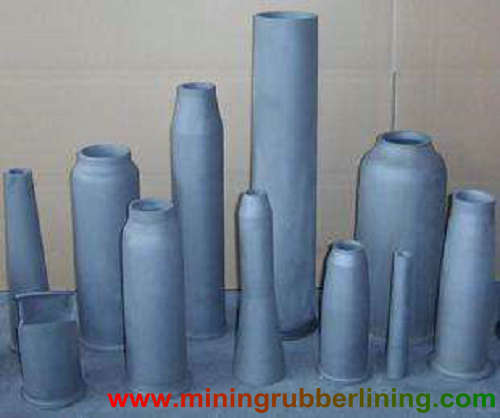

Silicon Carbide Nozzles | SIC Ceramic Nozzle

Silicon Carbide Nozzles Is One Special Ceramic Nozzle, SIC Nozzle Is Name For Short For Silicon Carbide Ceramic Nozzles

Manufacturing Process:

Silicon Carbide Nozzle Is a New Ceramic Material.

1. Blank Refining Technology, The Rough Forging Blank Is Replaced By Forging Blank, Which Saves The Cost Of Raw Materials And Also Saves The Processing Cost.

2. Drilling Technology, The Original Mechanical Drilling Has Been Changed To Computer-Controlled Laser Drilling And Electrolytic Drilling, a Smaller Machining 0.1 Mm Hole.

3. Welding Technology, The Traditional Welding Is Mainly Resistance Welding And Argon Arc Welding, Now To Progress For The Use Of High Temperature Vacuum Brazing And High Energy Density Electron Beam Welding.

4. Plane Grinding Technology, Using Single Disk Plane Grinding Machine Can Process More Smooth And Fine Products, Its Parallelism Can Reach 0.0003 Mm..

SIC Nozzle Has The Characteristics Of High Temperature Resistance, Oxidation Resistance, High Strength, Cold Resistance And Heat Resistance, Good Thermal Shock Resistance, Small High Temperature, Good Thermal Conductivity, Wear Resistance, Corrosion Resistance And So On.

Mechanical Properties:

Silicon Carbide Nozzle Is Widely Used As Energy Saving Refractory In High Temperature Kiln.

SIC Nozzle Not Only Has Excellent Mechanical Properties At Room Temperature, Such As High Bending Strength, Excellent Oxidation Resistance, Good Corrosion Resistance, High Wear Resistance And Low Friction Coefficient, But Also High Temperature Mechanical Properties (Strength, Creep Resistance, Etc.) Are Better In Known Ceramic Materials.

Hot Pressing Sintering, No Pressure Sintering, Hot Isostatic Pressing Sintering Materials, Its High Temperature Strength Can Be Maintained Until 1600℃, Is a Better Material In Ceramic Materials. Oxidation Resistance Is Also Better In All Non-Oxide Ceramics.

Silicon Carbide Nozzle With Excellent Resistance To Rapid Cooling And Heat And Wear Resistance, Oxidation Resistance, High Strength, No Slag, No Cracking, Long Service Life, Easy Replacement, Is An Ideal Fire Spraying Kiln Equipment Such As Roller Kiln, Tunnel Kiln, Shuttle Kiln And So On.

It Is Suitable For The Use Of Natural Gas, Liquefied Gas, Gas, Diesel Oil And Other Industrial Kiln Nozzles In Ceramic, Chemical, Glass, Metallurgy And Other Fields, Which Can Effectively Control The Balance Of Temperature In The Kiln.

In The Process Of Use, Silicon Carbide Ceramic Nozzle Will Inevitably Have Some Or Large Or Small Failure Problems, So How To Avoid The Phenomenon Of Blockage?

1. Choose To Buy Silicon Carbide Nozzle, Need To Choose Professional Anti-Blocking Silicon Carbide, Can Avoid Problems In The Later Use Process.

2. Jin Ruida Reminds Everybody, To Be Possible To Guarantee The Diameter, The Installation Nozzle Needs To Consider Whether The Coverage Rate Can Be Satisfied First, When The Coverage Rate Is Satisfied, Should Install As Few Nozzles As Possible To Ensure The Diameter.

3. The Long Washing Of Flue Gas Will Form a Lot Of Solid Waste In The Nozzle, The Manufacturer Recommends That The User Check And Repair Its Filtration Condition Regularly.

4. If The Blockage Of The Nozzle Is More Serious, It Is Necessary To Stop In Time For Inspection And Maintenance, And Clean And Replace It If Necessary, So As To Ensure The Normal Operation Of The Nozzle.