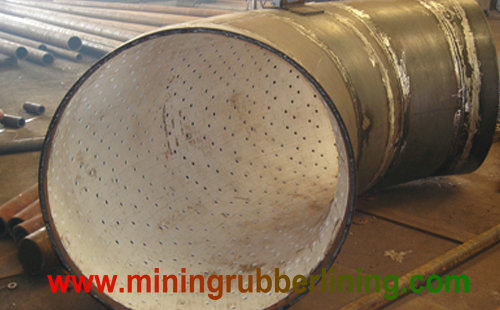

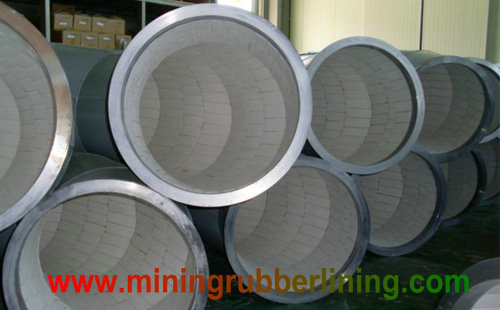

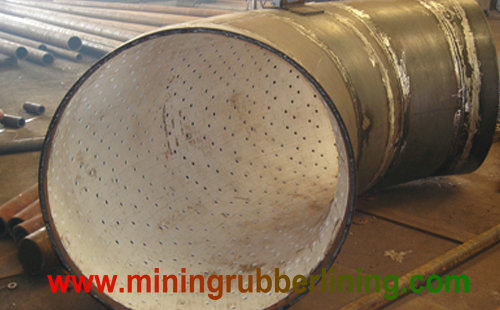

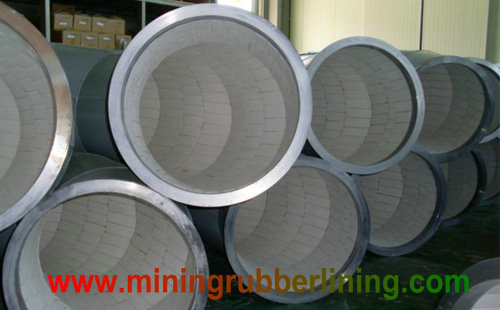

Ceramic Lined Pipe Is Made By High-Tech Production Process-Self-Triggered High-Temperature Clutch Synthesis. The Tube Is Composed Of Corundum Ceramic, Transition Layer And Steel Layer From Inside To Outside, Respectively. The Ceramic Layer Is a Dense Corundum Porcelain (Al2O3) Formed At High Temperature Above 2200℃, And a Solid Combination Is Formed With The Steel Pipe Through The Transition Layer.

Introduction Note

Ceramic Lined Steel Pipe Full Name Ceramic Lined Composite Steel Pipe.

Because The Composite Pipe Has Brought Into Full Play The Characteristics Of High Strength, Good Toughness, Impact Resistance, Good Weldability And High Hardness, High Wear Resistance, Corrosion Resistance And Heat Resistance Of Corundum Porcelain, It Overcomes The Characteristics Of Low Hardness, Poor Wear Resistance And Poor Ceramic Toughness Of Steel Pipe. Therefore, The Composite Pipe Has Good Comprehensive Properties Such As Wear Resistance, Heat Resistance, Corrosion Resistance, Mechanical Impact And Thermal Impact Resistance, And Good Weldability. Is An Ideal Wear-Resistant And Corrosion-Resistant Pipe For Conveying Particulate Materials, Grinding, Corrosive Media, Etc.

Because The Pipe Has Wear Resistance, Corrosion Resistance And Heat Resistance, It Can Be Widely Used In Electric Power, Metallurgy, Mining, Coal, Chemical Industry And Other Industries As Conveying Sand, Stone, Pulverized Coal, Ash, Aluminum Liquid And Other Grinding Particulate Materials And Corrosive Media, Is An Ideal Wear-Resistant Pipe.

Application In Metallurgy And Electric Power Industry

Metallurgical, Electric Power Industry Transport Pulverized Coal, Ash, Mud, Limestone Paste Slurry And So On Need To Consume a Large Amount Of Metal Pipes Every Year. Using Ceramic Lined Pipe To Replace Other Pipes Has The Characteristics Of High Wear Resistance, Long Life, Convenient Installation And Remarkable Economic Benefit. Through The Industrial Operation Of Shandong Liaocheng Changrun Thermal Power Plant, Liaocheng Zhonghua Power Plant, Beijing Beixin Building Materials Group, Henan Hebi Power Plant, Gansu Pingliang Power Plant, Taiyuan Coal Preparation Plant, Hunan Shimen Power Plant, Hebei Jinniu Energy Co., Ltd. Ge Quan Coal Preparation Plant, Xingtai Coal Preparation Plant And So On, Its Operating Life Is More Than Ten Times Or Even Dozens Of Times That Of Steel Pipe.

Application In Mining And Coal Industry

Mine: Mine Filling, Concentrate Powder And Tailings Transportation Wear And Tear The Pipeline Seriously, The Previous Use Of Ore Powder Transportation Pipeline Such As Panzhihua, Daye Ore And Other Service Life Less Than One Year, Changed To This Pipe Can Increase The Life Of About 5 Times.

Coal: Coal Preparation And Long-Distance Pipeline Coal Transport Is Generally Wet Transport, Requires That The Transport Pipe Is Both Wear-Resistant And Corrosion-Resistant, The Use Of This Pipe Can Be Used As a Long-Lived Transport Pipe, The Economic Benefits Are Considerable.

Other

(1) The Tube Is Non-Polluting And Non-Adhesive Molten Aluminum. It Is An Ideal Material To Manufacture Aluminum Melting Equipment, Liquid Aluminum Conveying Pipe And Liquid Lifting Pipe Which Are Sensitive To Iron Pollution And Need To Be Cleaned And Repaired By Heavy Labor After Use.

(2) The Ceramic Lined Pipe Has Good Wear Resistance And Heat Corrosion Resistance. Suitable For Conveying Corrosive Materials Containing Solid Particles, High Temperature Corrosive Gas, Sulfur-Containing Geothermal Water And Other Corrosive Media.

Characteristics

Characteristics Of SHS- Vineburn Ceramic Composite Pipe

Wear Resistance

The Ceramic Composite Tube Can Reach 9.0 Equivalent To Above Hrc90 Due To The Inner Lining Layer Of Corundum Ceramic (a-Al2O3). Therefore, The Grinding Medium Delivered By Metallurgy, Electric Power, Mining, Coal And Other Industries Has High Wear Resistance. It Is Confirmed By Industrial Operation That Its Wear-Resistant Life Is Ten Times Or Even Dozens Times That Of Quenched Steel.

Small Running Resistance

Because The Inner Surface Of Shs Ceramic Composite Pipe Is Smooth And Never Rusted, It Is Not Like The Convex Spiral Line On The Inner Surface Of Seamless Steel Pipe. The Inner Surface Smoothness Of The Inner Surface Is Better Than That Of Any Metal Pipe, And The Clear Resistance Coefficient Is 0.0193, Which Is Slightly Lower Than That Of Seamless Pipe. Therefore, The Tube Has The Characteristics Of Low Running Resistance And Can Reduce The Operating Cost.

Corrosion Resistance, Scale Protection

Because The Steel Ceramic Layer Is (a-Al2O3), It Is Neutral. Therefore, It Has The Characteristics Of Acid And Alkali Resistance And Seawater Corrosion Resistance, As Well As Anti-Scaling And So On.

Good Temperature Resistance And Heat Resistance

Due To This Corundum Ceramic (a-Al2O3), Which Is a Single Stable Crystalline Structure. As a Result, The Composite Tube Can Operate Normally For a Long Time In The Temperature Range ℃-50-700. The Material Line Expansion Coefficient 6-8×10-6/0 C, Is About 1/2 Of The Steel Pipe. The Material Has Good Thermal Stability.

Low Construction Cost

Ceramic Lined Pipe Is Light In Weight And Suitable In Price. It Is 50% Lighter Than The Cast Stone Pipe With The Same Inner Diameter ,20-30% Lighter Than The Wear-Resistant Alloy Pipe, And Wear-Resistant And Corrosion-Resistant, Because Of The Long Service Life, So That The Cost Of Support And Hanger, Handling, Installation And Operation Costs Are Reduced. By Comparing The Project Budget And Engineering Practice Of The Relevant Design Institute And The Construction Unit, The Project Cost Of The Pipe Is Equal To That Of The Cast Stone, And The Project Cost Is Reduced By About 20% Compared With The Wear-Resistant Alloy Pipe.

Easy Installation

Due To The Light Weight Of The Tube And Good Welding Performance. Therefore, Welding, Flange, Quick Connection And So On Can Be Adopted, The Construction And Installation Is Convenient, And The Installation Cost Can Be Reduced.

Other Knowledge

Ceramic Lined Pipe And Traditional Steel Pipe, Wear-Resistant Alloy Cast Steel Pipe, Cast Stone Pipe And Steel Plastic,

Rubber Lined Pipe And So On Have Essential Difference. The Outer Layer Of Ceramic Steel Pipe Is Steel Pipe, And The Inner Layer Is Corundum. Corundum Layer Vickers Hardness Up To 100-1500(Rockwell Hardness 90-98), Equivalent To Tungsten Cobalt Hard Gold. The Wear Resistance Is More Than 20 Times Higher Than That Of Carbon Steel Pipe, Which Is Much Superior To The Performance Of Corundum Grinding Wheel Which Is Usually Bonded. Now Corundum Grinding Wheel Is Still The Main Grinding Wheel Of Various Grinding Machines. The Corundum Layer In The Ceramic Steel Pipe Can Wear Out The Corundum Grinding Wheel. The Wear Resistance Of Ceramic Steel Pipe Mainly Depends On The Corundum Layer With a Thickness Of Several Millimeters In The Inner Layer, And Its Morse Hardness Is 9, Second Only To Diamond And Silicon Carbide, And Its Hardness Is The Highest Among All Oxides.

The Inner-Lined Ceramic Wear-Resistant Steel Pipe Is Made By Self-Propagating High Temperature Synthesis —— Centrifugal Method. The Corundum Melting Point In Ceramic Steel Pipe Is 2045℃. The Corundum Layer And Steel Layer Have Special Structure And Special Stress Field Due To Technological Reasons. The Ceramic Layer Is Subjected To Compressive Stress At Room Temperature, And The Steel Layer Is Subjected To Tensile Stress, Which Is Unified In Opposition And Forms a Balanced Whole. Only The Temperature Rises To More Than 400℃. Due To The Difference Of The Thermal Expansion Coefficient Between The Two, The New Stress Field Produced By The Thermal Expansion And The Original Stress Field In The Ceramic Steel Pipe Cancel Out Each Other, So That The Ceramic Layer And The Steel Layer Are In Free Equilibrium. As The Temperature Rises To 900℃ The Inner-Lined Ceramic Wear-Resistant Steel Pipe Is Put Into The Cold Water, Repeatedly Soaked For Many Times, The Composite Layer Does Not Crack Or Crack, Showing The Unparalleled Thermal Impact Resistance Of Ordinary Ceramics. This Performance Is Very Useful In Engineering Construction, Because Its Outer Layer Is Iron And Steel, And The Inner Layer Heating Does Not Crack, In Construction, Flange, Blow-Out, Explosion-Proof Door And So On Can Be Welded, But Also Can Be Connected By Direct Welding Method, Which Is Better Than Wear-Resistant Cast Stone Pipe, Wear-Resistant Cast Steel Pipe, Rare Earth Wear-Resistant Steel Pipe, Bimetallic Composite Pipe, Steel Plastic Pipe, Steel Rubber Pipe In Construction Is Not Easy To Weld Or Can Not Be Welded. The Inner-Lined Ceramic Wear-Resistant Steel Pipe Has Good Mechanical Impact Resistance, And The Composite Layer Does Not Break Off When It Is Transported, Installed And Knocked, And The Self-Weight Bending Deformation Between The Two Supports.

At Present, The Practice Of Dozens Of Thermal Power Plants Shows That The Lining Ceramic Wear-Resistant Steel Pipe Has High Wear Resistance And Strong Resistance To Fluid Scour. In The Primary Air Pipe, The Bend Pipe Wear Is The Fastest, And The Wear Resistance Of The Lined Ceramic Wear-Resistant Steel Pipe Bend Is More Than 5 Times Higher Than That Of The Thick Wall Wear-Resistant Cast Steel Bend.

In Practice, The Ceramic Lined Pipe Is Opened And Observed After 1-2 Years Of Use, And The Composite Layer Has No Obvious Wear Or Shedding. In The Same Specification And Unit Length Of Pipe, The Weight Of Lined Ceramic Wear-Resistant Steel Pipe Is Only About 1/2 Of That Of Wear-Resistant Cast Steel Pipe Or Bimetallic Composite Pipe, And Its Engineering Cost Is Reduced By 30-40% Per Meter. Ceramic-Lined Wear-Resistant Steel Tubes Used In Corrosive Or High Temperature Places Are Only Priced At a Fraction Of Stainless Steel Tubes, Nickel-Titanium Tubes.

Fluid Pipeline Transportation Is Not Only Used In Power Industry, But Also In Metallurgy, Coal, Petroleum, Chemical, Building Materials, Machinery And Other Industries. When Conveying Grinding Materials (Such As Ash, Pulverized Coal, Mineral Powder, Tailings Cement, Etc.), There Is a Problem Of Fast Pipe Wear, Especially When The Pipe Is Worn Fast; When Conveying Strong Corrosive Gas, Liquid Or Solid, There Is a Problem That The Pipe Is Corroded And Destroyed Quickly; And When Conveying Materials With High Temperature In The Pipeline, There Is a Problem That The Use Of Heat-Resistant Steel Pipes Is Very Expensive. Ceramic-Lined Wear-Resistant Steel Pipe Market, These Problems Are Solved.