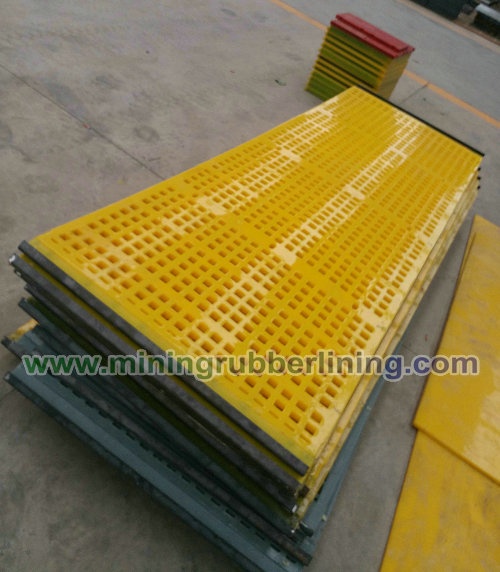

Tensioning Screen Panels Also Be Named As Tensioned Sieve Panels . Our Polyurethane Tension Screen And Rubber Tension Screen Can Greatly Improve The Screening Performance, Very Wear-Resistant In The Use Process, Can Solve More Rigorous Screening Work. Products Can Be Divided Into Coarse-Hole Screen, Medium-Hole Screen And Fine-Hole Screen.

TensioningScreen also Be Named AsTensionSieve.

The Materials Can Be Choose As Rubber , Industry Plastic , Polyurethane ( PU , Urethane )

Our Company Can ProduceTensionedScreen Or Sieve As Panels , Mesh , Sheet , Plate , Mats , Deck , Cloth , Media , Bends

Our Tension Screen Is Tailored To The Following Important Factors:

1, Sieve Panels SizeAfter Analyzing The Actual Working Conditions, We Began To Make Scientific Research On The Customization Of Polyurethane Screen. We Chose The Following Factors:

1, Rubber Or Polyurethane? Categories Of Polyurethane (Rubber)Our Tensioned Screen Can Be Used In Most Screening Fields, Especially In Fine Screening.

Our Polyurethane Elastic Screen Has Changed The Low Screening Ability Of Traditional Polyurethane Screen.

Our Elasticity And High Tension Properties Of Polyurethane Rubber Raw Materials And Our Perforation Technology Ensure High Screening Performance And Productivity.

Our Elastic Polyurethane Has Excellent Wear Resistance And Impact Resistance, Making Our Screen Durable.

Our Polyurethane Screen Is Especially Suitable For Drying Environment, Which Solves The Problem Of Blind Hole.

We Are Proud To Provide a Variety Of Screening Solutions To Provide Reliable Services To Our Global Customers.

Tension Screen Is Also Called Steel Wire Screen (Rubber Screen Or Polyurethane Screen Wrapped With Metal Wire And Stranded Core Wire Or Welded Screen)

The Material Has Beautiful Appearance, Bright Color, Light Weight, High Mechanical Strength, Heat Insulation, Sound Insulation, Corrosion Resistance, Good Weather Resistance, No Secondary Decoration, And Various Colors.

1. High Tensile Strength, Tear Strength, Excellent Wear Resistance, Good Resilience, Small Compression Permanent Deformation And Long Service Life.

2. It Has Strong Bonding Force With Metal Matrix And Is Not Easy To Rise And Fall Off.

3. High Surface Finish And Stable Size.

The High Strength Composite Polyurethane Rubber Tensioned Screen Belongs To The Technical Field Of Screening Equipment, Which Is Used To Solve The Problems Of Low Strength And Short Service Life Of Ordinary Metal Screen. The Utility Model Is Composed Of An Upper Net And a Tray. The Improvement Lies In That The Upper Net Is a Metal Net And The Tray Is a Polyurethane Tray. The Polyurethane Tray Is Situated Under The Metal Net. It Is a Grid With Vertical And Horizontal Intersections, And Its Warp And Weft Strips Are All Composed Of a Wire Rope Core And a Polyurethane Surface Layer.

The Above Improvement Gives The Utility Model Excellent Performance Different From That Of Ordinary Metal Screen. It Has High Strength, Stiffness And Bearing Capacity, And Can Effectively Reduce Vibration And Noise, Improve The Service Life Of The Screen. The Utility Model Can Be Made Into Screening Devices Of Various Shapes, And Is Especially Suitable For High Frequency Vibrating Screen With Electromagnetic Excitation. It Can Be Widely Used In Screening, Filtering, Dewatering, Desliming And Other Operations In Many Industries.

8 Mm X5 Mm Hole 1.2 m X5 M

8 Mm X12 Mm Hole 1.5 m X5 M

8mm X20mm Hole 2m X5m

It Is Suitable For Vibration Screening In Metallurgy, Coal, Chemical Industry, Construction And Many Other Departments. It Can Be Used As Fine-Grained Screening In Bulk Materials And Dry-Astringent Screening. It Can Also Be Used For Classification Of Some Corrosive Materials.

Contact: Sales Department

Phone: +86 138 10365943

Tel: +86 166 33372827

Email: sales@miningrubberlining.com

Add: No.910 Zhongshan West Road Qiaoxi District Shijiazhuang Hebei China