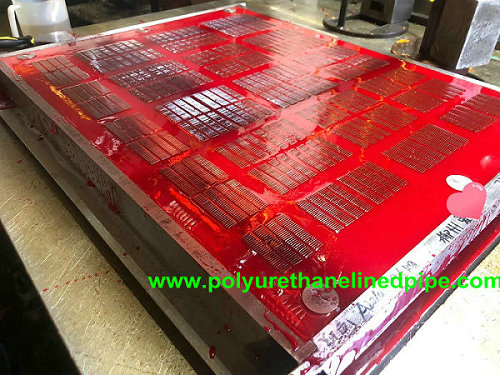

Dewatering Screen Panels Also Be Named As Dewatering Sieve Panels . It is Is a Kind Of Screen Used In Dewatering Machine, Which Is Mainly Used For Material Dewatering Or Fine Particulate Material Screening. Dewatering Screen Mesh Is Also Called Trough Screen Panels And Tailings Dewatering Screen Panels. Because The Shape Of Dewatering Screen Panels Is Generally Small, It Is Also Called Slit Screen Panels.

DewateringScreen also Be Named AsDewateringSieve.

The Materials Can Be Choose As Rubber , Industry Plastic , Polyurethane ( PU , Urethane )

Our Company Can ProduceDewateringScreen Or Sieve As Panels , Mesh , Sheet , Plate , Mats , Deck , Cloth , Media , Bends .

The Material Of Water Separating Screen Panels Can Be Divided Into Wear-Resistant Rubber And Wear-Resistant Polyurethane. But The Most Common One Is Polyurethane Dehydration Screen Panels. The Mesh Holes Of Rubber Dehydration Screen Panels Are Generally Larger, While The Mesh Holes Of Polyurethane Screen Panels Are Smaller, And The Minimum Is Up To 0.1 Mm.

The Structure:

Made Of Polyurethane Screen Panels Or Rubber Screen Panels With Metal Welded Frame. The Screen Panels Can Withstand Greater Pressure Or Impact Force.

Uses:

Dewatering Screen Boards Are Widely Used In Dressing Plants, Tailings Dewatering, Concentrate Dewatering, Sandstone, Mine Dewatering Screen Boards, Slime Dewatering Screen Boards, Tailings Dewatering Screen Boards, Sand Dewatering Screen Boards, Sand Vibration Screen Boards, Dewatering Screen Boards, Etc.

Characteristics:

1. High Wear Resistance, Water Resistance, Corrosion Resistance, Long Service Life.

2. The Screen Above The Dewatering Screen Panels Is Small, The Screen Below Is Large, The Screen Is Fine, It Is Not Easy To Clog, And The Screen Efficiency Is High.

3. Slit Screen Panels Has Assembled Structure. Single Screen Panels Is Small In Area, Light In Weight And Easy To Install. If Polyurethane Screen Panels Is Damaged, Only Damaged Parts Need To Be Replaced Without Large-Scale Replacement, Thus Saving Cost.

4. Installation Modes Are Various: Nail Type, Bolt Type, Track Type And Press Rod Type. Customers Can Customize The Installation Of Vibration Screens With Different Screen Panelss According To Their Needs.

Type Of Screen Panels:

The Size Of Polyurethane Dehydration Screen Is Generally Determined By The Screen Hole Size Of The Vibrating Screen Machine.

Size Of Polyurethane Screen Panels: 305*305, 305*610, 610*610, 500*600.

Clamp Type Vibration Screen Slot: 0.1, 0.2, 0.3, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0mm And So On.

Dehydration Equipment Suppliers Can Customize Dehydration Screen Boards Of Various Sizes. If You Need High Quality Polyurethane Dehydration Screen Panels, Please Contact Us.

Normally, The Dewatering Screen Will Not Be Damaged Within One Year. But When The Service Life Of The Dewatering Screen Expires, How To Replace The Dewatering Screen? What Should We Pay Attention To In The Exchange Screen? The Following Is a Detailed Introduction Process:

1. After The Dewatering Screen Frame Is Assembled Into The Screen Box According To The Requirements, Keep In Mind That The 50-70mm Screen Mesh Cut Out Should Be Extended Into The Corresponding Outlet To Prevent Mixing Phenomenon.

2. When Cutting, To Keep The Width Of Dewatering Screen Consistent With The Grid, The Length Of The Screen Must Be 50-70 Mm Longer Than That Of The Dewatering Screen.

3. Screen Device Must Be Tightened, Because The Tightening Of Screen Is An Important Factor Affecting The Power Of Dewatering Screening.

4. When Installing Net-Clearing Bouncing Balls, We Must Pay Attention To The Difficulty Of Screening Materials And The Number Of Eyes, Not Blindly Install Them.

5. If The Material Proportion Is Large Or The Mesh Number Of The Dewatering Screen Device Is High, The Appropriate Mesh Number Should Be Added Under The Screen. The Purpose Is To Play a Supporting Effect, Reduce The Pressure Of The Material On The Screen And Extend Its Service Life.

6. When Installing The Dewatering Sieve Press Plate, We Must Pay Attention To Its Smoothness And Lock It Evenly With a Strong Retractable Sponge Seal Belt, Because This Is Not Only The Key To Eradicate The Outbreak Of The Mixing Stage, But Also An Important Factor Affecting The Service Life Of The Vibrating Sieve Screen.

Contact: Sales Department

Phone: +86 138 10365943

Tel: +86 166 33372827

Email: sales@miningrubberlining.com

Add: No.910 Zhongshan West Road Qiaoxi District Shijiazhuang Hebei China