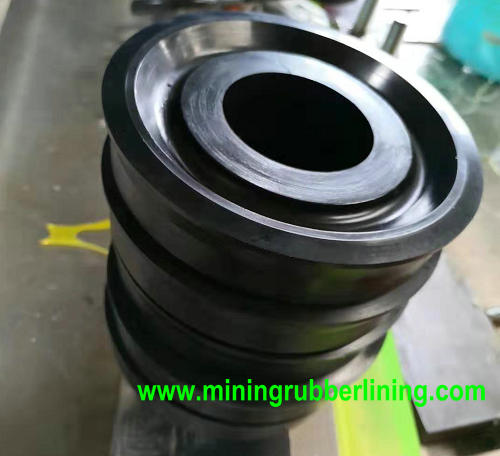

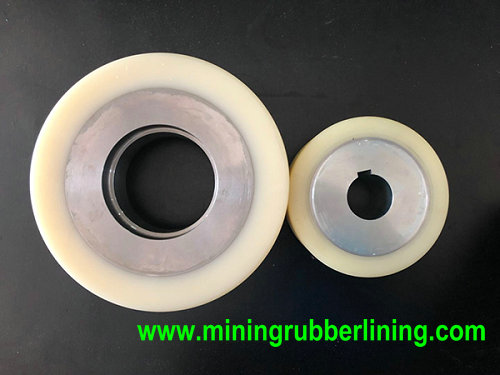

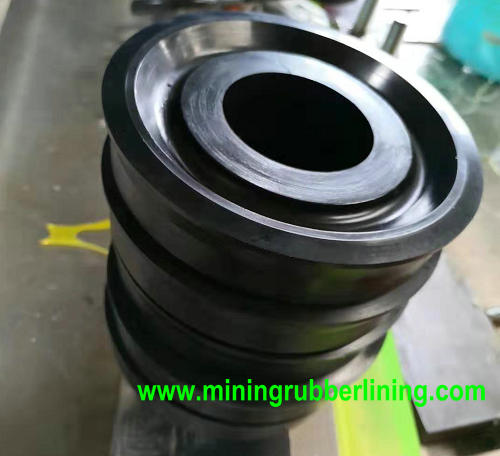

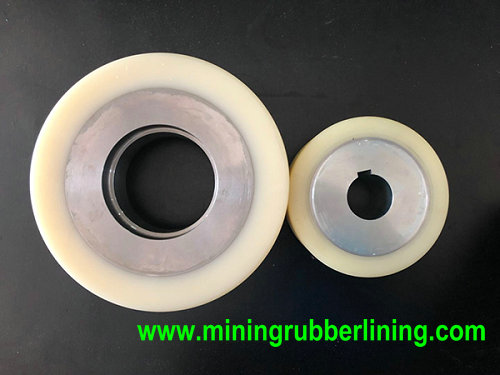

Polyurethane Wheels Also Named As Polyurethane Lined Wheels Or Polyurethane Coated Wheels . It Is Made Of Metal Core / Steel Core With Surface Polyurethane Coating . It Mainly Be Used For Wear Resistant Wheels , Add Working Life Time .

Polyurethane Wheels Is Generally Provided By The Customer To Wrap The Roller Core , Our Company Technical Personnel According To The Customer Color , Size And Hardness And Other Related Requirements For Polyurethane Processing , Polyurethane Wheels Processing Needs To Go Through The Following Process :

Clean The Iron Core Provided By The Customer : If It Is A New Cots Core Need To Clean The Oil Stain On The Core Surface And So On With Cleaning Agent ; If It Is An Old Cots Core, Need To Remove The Wrap Glue From The Outer Layer Of The Old Cots , At The Same Time Use Cleaning Agent To Clean The Remaining Glue On The Core Surface .

The Surface Of Cots Core Is Rough Treated : The Surface Of Cots Core Is Rough Treated To Increase The Adhesive Area Between Cots Core Surface And Adhesive .

Sand Blasting Treatment : Rough Treated Cots Iron Core Sand Blasting Treatment , Sand Blasting Will Be Based On The Cots Iron Core Material Selection Of Different Properties Of Sand To Sand Blasting . Sand Blasting Is To Make The Surface Of The Cots More Rough , After The Glue And Core Adhesive Better .

Gum Wrap : After The Above Treatment Of The Cots Core According To Customer Requirements For Glue Wrap .

Polyurethane Wheel Vulcanization : The Polyurethane Roller After The General Need 10-15 Hours Of Vulcanization Time , After Vulcanization , The Core Of The Polyurethane Roller And The Polyurethane Will Be Tightly Bonded , Polyurethane Wheel Forming .

Wrap Polyurethane Wheel Grinding : According To The Size And Shape Required By The Customer To Polish , Some Customers On The Top Roll Surface Requirements Of The Case , Need To Use A CNC Grinder For The Top Roller Mirror Grinding .

Application Of Polyurethane Lined Wheels In Manufacturing Enterprises :

1. Physical And Mechanical Performance Indicators Can Be Selected Through The Raw Materials And Formula Adjustment , Polyurethane Wheels A Certain Range Of Flexible Changes , So As To Meet The Unique Requirements Of Users For The Performance Of Products . Such As Hardness , Is Often An Important Index Of Products , Polyurethane Elastomer Can Be Made Not Only Shore A Hardness About 20 Soft Printing Cots , But Also Shore D Hardness More Than 70 Hard Rolled Cots , Which Is Difficult To Do By General Elastomer Materials , Can Be Suitable For Different Users . Polyurethane Elastomer Is A Polar Polymer Material Composed Of Many Flexible And Rigid Segments . With The Increase Of The Proportion Of Rigid Segments And The Density Of Polar Groups , The Original Strength And Hardness Of Elastomer Will Increase Accordingly .

2. Excellent Wear Resistance .

Polyurethane Wheels Wear Resistance Is Often Several To Dozens Times That Of Ordinary Polyurethane Materials In The Presence Of Wetting Media Such As Water And Oil . Metal Materials Such As Iron And Steel , Although Very Hard , But Not Necessarily Wear-Resistant ; Other Such As Rice Mill Cots , Coal Screen For Vibrating Screen , Sports Track , Crane Forklift For Dynamic Oil Sealing Ring , Elevator Wheel And Roller Skates , And So On Are Also Polyurethane Elastomer .

3. Various Processing Methods And Wide Applicability .

Polyurethane Wheels Elastomer Can Be Molded In The Same Plasticizing , Mixing And Vulcanizing Process As General Polyurethane ; Liquid Polyurethane Can Also Be Molded By Pouring Or Spraying , Filling , Centrifugal Molding ( Refers To CPU ) ; Granular Materials Can Also Be Made , Like Ordinary Plastics , By Injection , Extrusion , Calendering , Blow Molding And Other Processes ( Refers To ) . Molded Or Injection Molded Parts , In A Certain Range Of Hardness, Can Also Be Cut , Grinding , Drilling And Other Mechanical Processing . The Diversity Of Processing Makes The Application Of Polyurethane Elastomer Very Wide And The Application Field Is Expanding .

4. Oil Resistance , Ozone Resistance , Aging Resistance , Radiation Resistance , Low Temperature Resistance , Good Sound Permeability , Strong Adhesion , Excellent Biocompatibility And Blood Compatibility . And These Advantages Are Why Polyurethane Wheels Elastomer Are Widely Used In Military , Aerospace , Acoustic And Biological Fields .