Polyurethane Lined Elbow Also Named As Polyurethane Lined Bends . It Is Important Pipe Parts In The Polyurethane Steel Steel Pipeline. In The Pipeline System, The Pipe Fittings Of Polyurethane Lined Steel Elbow Mainly Change The Direction Of The Pipeline.

Partition By Angle: There Are 45 degree PU Lined Elbow , 90 degree PU Lined Elbow , 180 degree PU Lined Elbow. Three Most Commonly Used, In Addition To Engineering Needs Including 60 degree PU Lined Elbow . And Other Abnormal Angle Elbow. The External Steel Pipe Parts Of The Elbow Are Cast Iron, Stainless Steel, Alloy Steel, Malleable Cast Iron, Carbon Steel, Non-Ferrous Metals And Plastics.

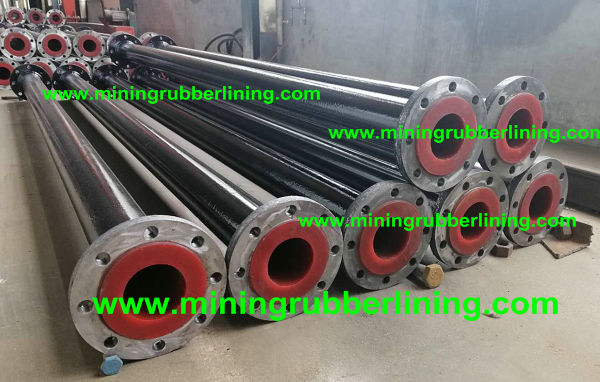

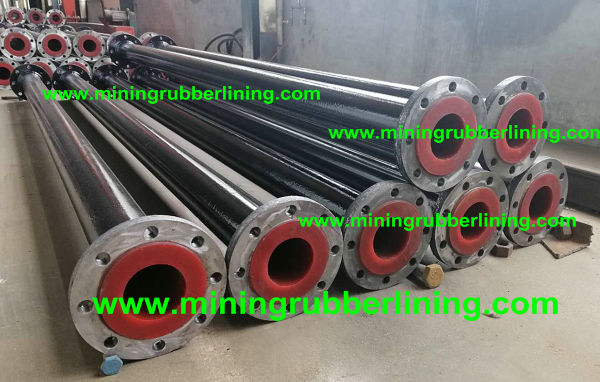

The Ways Of Connecting With The Lined Polyurethane Steel Pipe Are: Direct Welding (The Most Commonly Used Way) Flange Connection, Hot Melt Connection, Electric Melting Connection, Thread Connection And Socket Connection, Etc.

According To The Production Process Can Be Divided Into: Polyurethane Lined Welding Elbow, Polyurethane Lined Stamping Elbow, Polyurethane Lined Push Elbow, Polyurethane Lined Casting Elbow, Polyurethane Lined Butt Welding Bend, Etc.

Other Name : Polyurethane Lined 90 Degree Bend , Polyurethane Lined Right Angle Bend, Etc.

Polyurethane Lined Elbow ( Bend ) Pipe Has Excellent Comprehensive Properties Such As Wear Resistance, Acid Resistance, Scale Prevention, Radiation Resistance, Hydrolysis And Aging Resistance, High Elasticity And Mechanical Impact Resistance.

Polyurethane Is a Kind Of Polymer Wear-Resistant Material. It Is Widely Used In Daily Life, Such As Paint And Paint In Furniture, Refrigerator And Freezer In Household Appliances, Roof Waterproof Insulation Layer And Interior And Exterior Wall Paint In Construction Industry, Etc. Can Also Be Made Into Various Polyurethane Materials Such As Polyurethane Sole, Polyurethane Fiber, Polyurethane Sealant, Etc. In General, Polyurethane Products Have Wide Range Of Properties, Strong Adaptability, Biological Aging Resistance And Moderate Price.

Advantages Of Pipe Elbow Polyurethane Liner :

1. Wear Resistance Is Good.

Because The Polyurethane Lining Has Better Elasticity, But Under The Impact Of The Medium, Polyurethane liner Is Forced To Compress Under The Action Of External Force, And After The External Force Disappears, The Polyurethane Is Restored To Its Original State. This Kind Of Flexible Steel Greatly Reduces The Wear Caused By The Direct Strong Scour Of The Medium On The Inner Wall Of The Pipe, And Its Wear Resistance Life Is More Than Ten Times That Of The Steel Pipe.

2. Anti-Scaling.

Polyurethane Lining Elastomer Has a Symmetrical Molecular Structure, Which Can Not Form a Ca2+ To The Slurry, Co32-,Hco3,Oh Plasma Adsorption, And Can Not Form a Scale Layer. According To The Smooth Inner Surface And Good Elasticity, It Can Prevent The Adhesion Of The Scale Layer, So It Has Better Anti-Scaling And Anti-Scaling Performance.

3. Running Resistance Is Small.

The Smooth Tool On The Inner PU Lining Surface Is Transparent And The Roughness Of The Inner Wall Is 0.082, Which Can Reduce The Running Cost.

4. Water Resistance Stability, Good Aging Resistance.

It Will Not Be Like Rubber Products In Water Will Occur Swelling Phenomenon And Affect The Performance Of Use.

5. Combine.

The Pipe Bends Polyurethane Lining Is Closely Combined With The Polyurethane Lined Pipe, And Special Process Is Adopted. At Present, It Is Widely Used In Ocean, Ferrous Metal Mine, Non-Ferrous Metal Mine, Mineral Processing Process Pipeline Of Non-Metallic Mine, Tailings Transportation Pipeline, Coal Supply And Ash Removal System Transportation Pipeline Of Thermal Power Plant, And Petroleum, Chemical Industry, Cement. Pipeline Transportation In Grain And Other Industries.