Polyurethane Screen Panels Also Named As PU Sieve Panels Or Urethane Screen , It Is An Important Part Of Vibrating Screen Machine Used To Complete The Process Of Screening Materials . Each Vibrating Screen Machine Should Choose a Urethane Screen Panels . That Meets Its Working Requirements .

The Structure Of The Screen Panels Is Different According To The Characteristics Of The Material , The Material And Various Parameters Of The Sieve Machine Have a Certain Impact On The Screening Ability, Efficiency , Run-Rough Rate And Life Of The Vibrating Screen . Different Materials And Different Places Should Choose Different Polyurethane Panels , To Achieve The Best Screening Effect .

Polyurethane Screen Panels Should Have Sufficient Strength , High Opening Rate And Not Easy To Plug Holes And Other Properties . As The Vibrating Screen Vibrates , The Material With Different Shapes And Sizes , The Material Size , Under The Action Of Vibration Force , The Material With Different Particle Size Is Screen Panels Separated To Achieve The Purpose Of Grading .

Classification And Application Polyurethane Screen Panels Vibrating Sieve

According To The Particle Size Of The Sifted Material And The Process Requirements Of The Sifting Operation , The Screen Panels Can Generally Be Divided Into The Following Categories :

1. Bar Polyurethane Screen Panels :

A Bar Screen Panels Is Composed Of a Group Of Steel Bars Arranged In Parallel And Having a Certain Section Shape . The Bars Are Arranged In Parallel, And The Spacing Between The Bars Is The Size Of The Sieve Hole . Bar Sieve Surface Is Generally Used For Fixed Sieve Or Heavy Vibrating Screen , Suitable For Screening Coarse Grain Grade Materials With Particle Size Greater Than 50 MM .

2. Punching Polyurethane Screen Panels :

Punching Polyurethane Panels Is Generally Made Of Round , Square Or Rectangular Sieve Holes Punched On Steel Plates Of 5-12 MM Thick . Compared With The Polyurethane Screen Panels Of Circular Or Square Sieve Holes , The Sieve Surface Of Rectangular Sieve Holes Usually Has a Large Effective Area , Light Weight And High Productivity , Which Is Suitable For The Treatment Of Materials With High Moisture Content , But The Separation Accuracy Of Sieving Is Poor .

3. Woven Mesh Polyurethane Screen Panels :

Braided Mesh Polyurethane Screen Panels Is Made Of Metal Wire With Bending Buckle , The Sieve Hole Shape Is Square Or Rectangular . Its Advantages Are : Light Weight, High Opening Rate ; And In The Screening Process , Because The Wire Has a Certain Elasticity , And Make High Frequency Vibration , So That The Fine-Grained Material Stuck To The Wire Off , Thus Improving The Screening Efficiency . Suitable For The Screening Of Medium And Fine Grade Materials . But The Disadvantage Is Shorter Life Span .

There Are Two Kinds Of Woven Mesh Sieve Surface : Coarse Hole And Fine Hole . The Manufacturing Material Of Coarse Hole Braided Screen Has Low Carbon Structure Steel Wire , Spring Steel Wire And Stainless Steel Wire , Etc. Screen Size Generally :4-125 Mm , Steel Wire Diameter 1.6-12.5 MM . The Fine Hole Braided Net Is Generally Made Of Low Carbon Steel , Brass , Tin, Tin Watch Copper And Stainless Steel , Etc. , With Special Knitting Machine . And The Hole Opening Rate Is 36%-80% , And The Sieve Hole Size Is :0.03-16 MM . The Applicable Sieve Body Angle Is : 18°-30°.

4. Seam Polyurethane Screen Panels :

Made Of Stainless Steel As Sieve Strip , There Are Three Structural Types : Piercing Strip , Welding Type And Braided Type . The Shape Of The Sieve Section Polyurethane Screen Panels The Slit Is Circular , And The Width Of The Slit Can Be 0.25 Mm、0.5mm、0.75mm、1mm、2mm, Etc.

Bar Seam Polyurethane Screen Panels Suitable For Dehydration, Demineralization And Desliming Of Fine Particles .

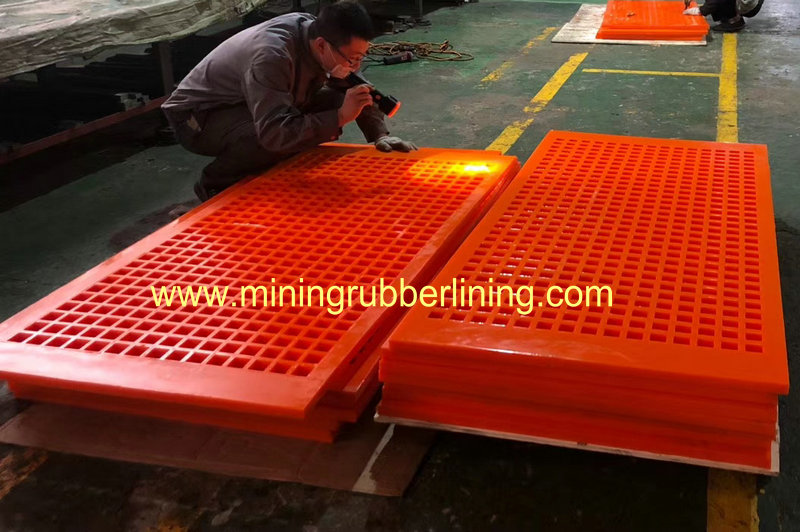

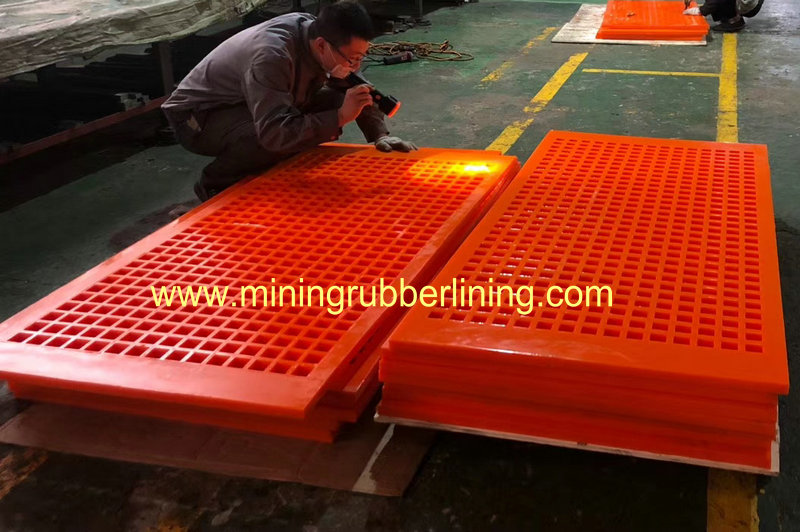

5.PU Screen Panels :

PU Screen Panels Is a Kind Of Reticular Product Produced From Polyurethane . The Pore Shape Of Urethane Screen Panels Is Divided Into : Slit , Rectangle , Circle , Square And So On . It Has Good Wear Resistance , Oil Resistance , Hydrolysis Resistance , Bacteria Resistance And Aging Resistance . It Is Widely Used In Coal Washing Plant , Coking Plant , Mine , Power Plant , Dredging Company , Metallurgy , Petroleum , Petrochemical And Other Industries .

PU Screen Panels Hole Shapes Are : Comb Teeth , Square Hole , Long Hole , Round Hole And Slit Type . Graded Particle Size Of Material : Mm.0.1-79polyurethane Panels Whether It Can Be Tensioned And Firm Evenly When Installed On The Screen Box Has a Great Influence On The Screening Efficiency And Service Life Of The Screen Surface . Usually , The Punching Polyurethane Panels And Slits Screen Panels Fixed With Wooden Wedges ; The Braided Mesh With Smaller Mesh Diameter And The Punching Screen Surface With Thickness Less Than 6 Mm Are Fixed With Retractor ; The Braided Mesh With Mesh Diameter Greater Than 9.5 Mm And The Punching Screen Panels With Thickness Greater Than 8 Mm Are Fixed With Press And Screws .

PU Screen Panels Advantages :

1. Wear Resistance Is Good : Long Service Life , Its Wear Resistance Is 3-5 Times Of Steel Screen Panels , More Than 5 Times Of Ordinary Rubber Screen Panels .

2. Reduce The Maintenance Rate : PU Screen Panels Is Not Easy To Damage , Long Service Life , So Can Greatly Reduce The Amount Of Maintenance And Stop Production Maintenance Loss .

3. The Total Cost Of Is Low : Although The PU Screen Panels Of The Same Specification ( Area ) Is Higher Than The One-Time Investment Of Stainless Steel Screen Panels ( About Twice ) , The Economic Application Is The Best Choice Because The PU Screen Panels Life Is 3-5 Times That Of Stainless Steel Screen Panels And The Number Of Maintenance And Replacement Is Less .

4. Moisture Resistance : Can Work Under The Condition Of Water Cut-Off , And In The Case Of Water , Oil And Other Media , Polyurethane And Material Friction Coefficient Decreased , More Conducive To Screen Penetration , Improve Screen Resolution , And Can Avoid The Adhesion Of Wet Particles , At The Same Time Due To The Reduction Of Friction Coefficient , Wear Reduced , Service Life Increased .

5. Corrosion Resistance : Non-Flammable , Non-Toxic And Tasteless .

6. Anti-Clogging : Because The Sieve Hole Design Is Reasonable , The Polyurethane Screen Panels Manufacturing Process Is Unique , The Particles Of The Limit Size Will Not Block The Sieve Hole .

7. Good Vibration Absorption Performance Of The Strong Silencing Ability , Can Reduce Noise , And Can Make The Sieve In The Process Of Vibration Is Different .

8.PU Screen Panels Has Self-Cleaning Effect , So Screening Efficiency Is High .

9. Saving Energy And Reducing Consumption , The Specific Gravity Of Polyurethane Is Small , Which Is Much Lighter Than The Weight Of The Same Size Rigid Screen , Thus Reducing The Load Of The Screen Machine , Saving Electricity Consumption , And Prolonging The Life Of The Screen Machine .

Our Company Specializes In The Production Of PU Screen Panels , Polyurethane Screen Panels , Polyurethane Discontinuous Screen Panels , Polyurethane Continuous Screen Panels , Stainless Steel Polyurethane screen Panels , Polyurethane Screen , Polyurethane Lining , Polyurethane Rail Seat , Coal Mine Dewatering PU Screen Panels , Ceramic Rod Polyurethane Screen Panels , Frame Polyurethanes Creen Polyurethane Screen Panels , S-Type Polyurethane Screen Panels , Pin Type PU Screen Panels , Tension Polyurethane Screen Panels And Other Polyurethane Screen Panels Manufacturers Produce Products With High Opening Rate , Light Weight , Good Shock Absorption , Low Noise And Good Wear Resistance .

The Introduction Of This Product Technology , Filled a Blank Product In China , The Product Structure Is Reasonable , The Quality Is In The International Leading Level , Easy To Install , Advanced Manufacturing Technology . Compared With Imported Similar Products , With Outstanding Price Advantages , For Domestic Users Who Do Not Use Imported Equipment To Provide The Best Choice , Please The Majority Of Customers Rest Assured To Buy .