Rubber Shock Absorbers ( Rubber Vibration Dampening Pads ) Is Characterized By High Elasticity And Viscosity. The Elasticity Of Rubber Is Produced By The Change Of Its Crimp Molecular Conformation. The Interaction Between Rubber Molecules Will Hinder The Movement Of Molecular Chains, Thus Showing The Characteristics Of Viscous Damping, So That The Stress And Strain Are Often In An Unbalanced State.

Rubber Shock Absorbers Principles

The Long Chain Molecular Structure And The Weak Secondary Force Between The Molecules Make The Rubber Materials Exhibit Unique Viscoelastic Properties And Thus Have Good Shock Absorption, Sound Insulation And Buffer Properties. Rubber Components Are Widely Used To Isolate Vibrations And Absorb Shocks Because Of Their Hysteresis, Damping And Reversible Deformation.

The Hysteresis And Internal Friction Characteristics Of Rubber Are Usually Expressed By Loss Factor. The Larger The Loss Factor, The More Significant The Damping And Heat Generation Of Rubber, And The More Obvious The Shock Absorption Effect.

The Size Of The Loss Factor Of Rubber Material Is Not Only Related To The Structure Of The Rubber Itself, But Also To The Temperature And Frequency. The Loss Factors Of Natural Rubber (Nr) And Cis-Butadiene Rubber (Br) Are Smaller At Room Temperature. The Loss Factors Of Butadiene Rubber (SBR), Neoprene Rubber (Cr), Ethylene Propylene Rubber (Epr), Polyurethane Rubber (Pu) And Silicone Rubber Are Centered, While The Loss Factors Of Butyl Rubber (Hr) And Nitrile Rubber (Nbr) Are The Largest.

There Are Generally Five Kinds Of Rubber Materials Used For Shock Absorption, That Is, Nr,Sbr,Br Are Ordinary Rubber Materials; Nbr Are Used For Oil-Resistant Vulcanizates; Cr Are Used For Weather-Resistant Vulcanizates; Iir Are Used For High Damping Vulcanizates; Epr Are Used For Heat-Resistant Vulcanizates. Nr, Although The Loss Factor Is Small, It Has The Best Comprehensive Performance, Excellent Elasticity, Good Fatigue Resistance, Low Heat Generation, Small Creep, Good Adhesion With Metal Parts, Cold Resistance, Electrical Insulation And Processing Performance,

So NR Is Widely Used For Shock Absorption Purposes, And Can Be Modified With Br Or Cr When It Requires Low Temperature Or Weather Resistance. Nishiue And Other Shock Absorbers Made Of Metal Salts Containing - Oh Group Organic Acids With Nr、Br And Carbon Atom Number Greater Than 4 Have Better Durability. The Compression Permanent Deformation At 70℃×22 h And 40 And 148 h Is 17.0% And 11.7%, Respectively.

Rubber Vibration Dampening Pads Application

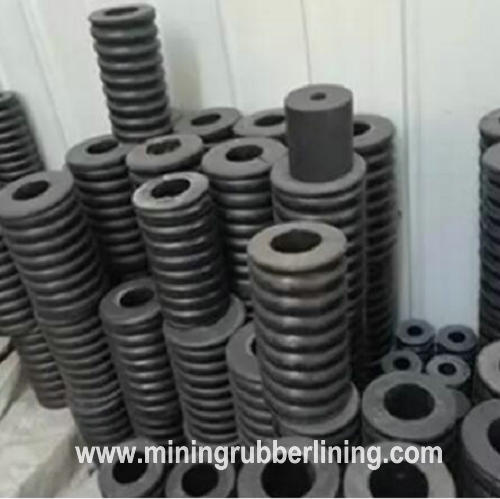

Rubber Shock Absorbers Are Mainly Rubber Shock Absorbers ( Vibration Dampening Pads ), Rubber Air Springs, Rubber Fenders, Sponge And Cork Rubber Shock Absorbers, Elastic Coupling Joints And Flexible Pipes.

For Example:

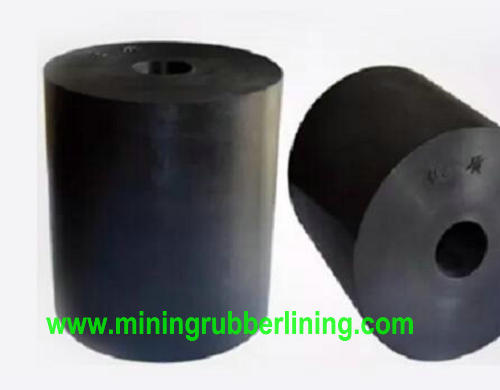

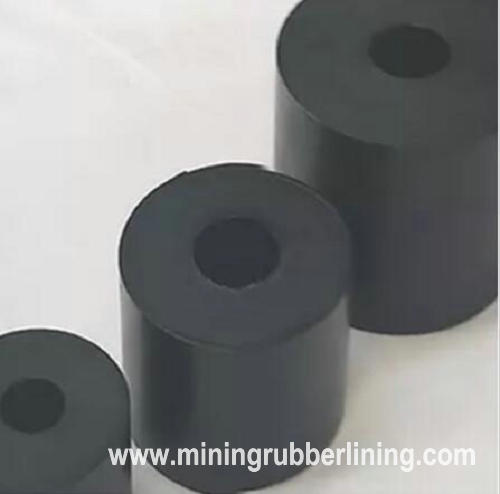

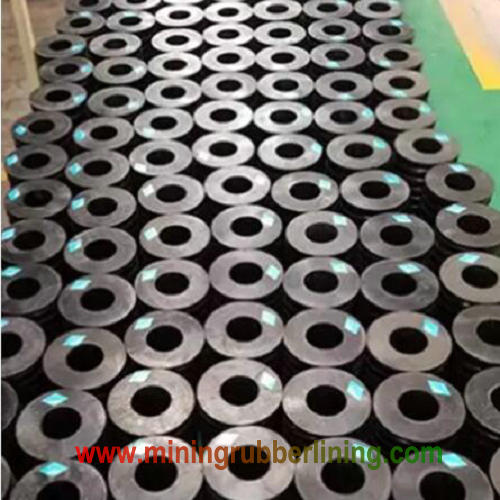

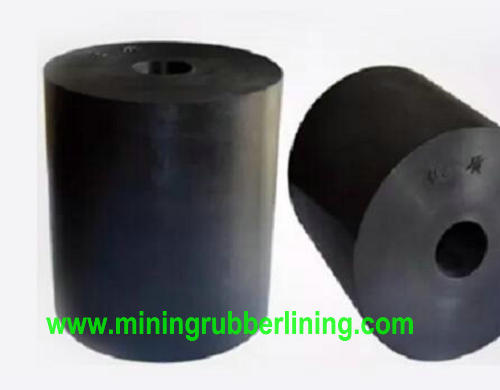

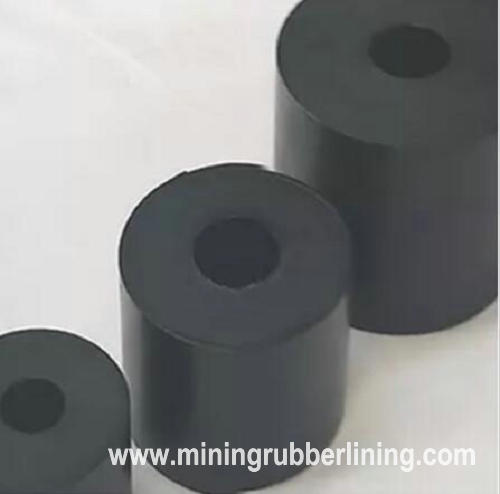

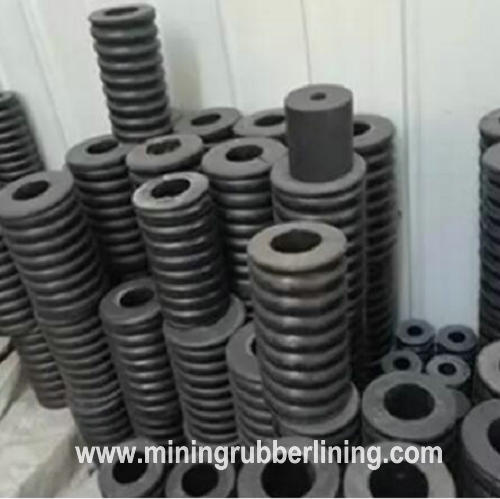

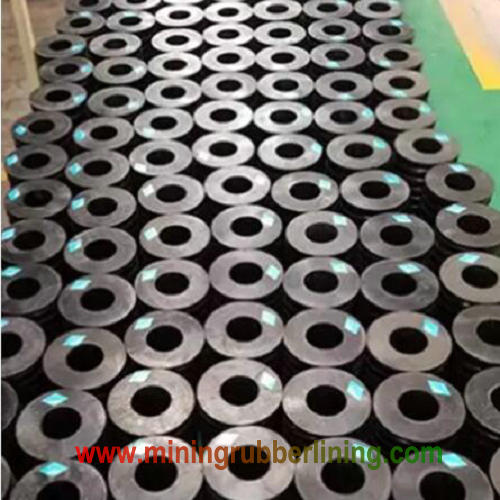

1.Rubber Shock Absorbers . Most Of Them Are Rubber And Metal Composite Products, With Double Plate Type, Cylindrical Type, Sheet Type And Other Forms, Which Are Used For Shock Absorption And Sound Insulation Of Various Machinery, Instruments, Axle And Pipeline.

2. Rubber Air Spring. It Is Better Than Metal Spring Shock Absorption And Impact Resistance, Mainly Used In Vehicles. Its Structure Is Similar To That Of Tire Without Inner Tire, With Cord Layer As Pressure Layer, With Airtight Rubber Layer Inside, And Protective Rubber Layer With Oil Resistance And Aging Resistance Outside.

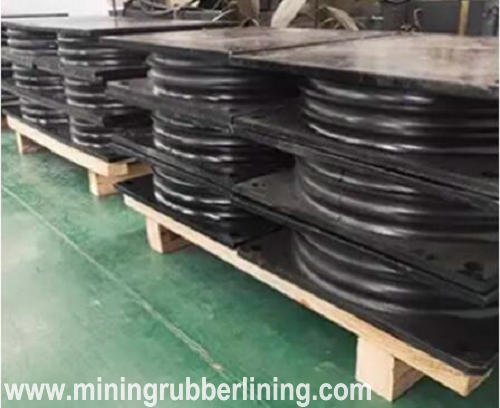

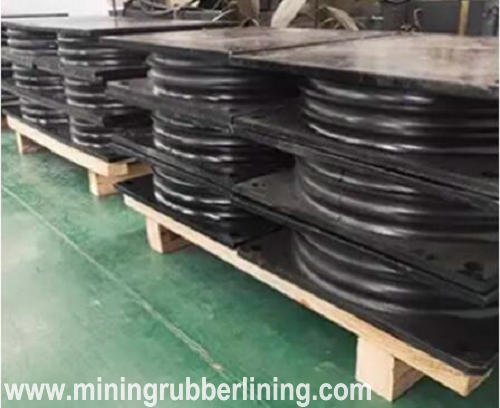

3. Rubber Bearings. Made Of Rubber Flakes Bonded To Rigid Materials (Steel Plate, Wire Mesh, Canvas). The Latter Can Increase The Compressive Strength Of The Support, But The Impact Of The Shear Strength Is Very Small. The Rubber Bridge Support Can Transfer The Bridge Load To The Pier And Abutment, At The Same Time, It Can Adapt To The Deformation Of The Bridge And Reduce The Vibration. Rubber Building Supports Can Reduce The Impact Of Subway And Surrounding Driving Vehicles And Earthquakes On Buildings.

4. Rubber Non-Slip Mat. Made From Rubber Tree To Collect Latex, Isopentadiene Polymer. Good Wear Resistance, High Elasticity, Breaking Strength And Elongation. Easy To Aging In The Air, Hot To Become Sticky, Easy To Expand And Dissolve In Mineral Oil Or Gasoline, Alkali-Resistant But Not Strong Acid. Advantages: Good Elasticity, Acid And Alkali Resistance.

Nowadays a Lot Of Domestic Rubber Anti-Slip Mat Can Be Said To Be a Dazzling Array, People Feel Dazzling, But The Real Anti-Slip Function Of Anti-Slip Mat In The End How Many? Rubber Anti-Skid Pad It Is a Collection Of a Variety Of Functions In One, Not Only Has The Basic Hydrophobic Anti-Skid Function, More Basic Super Wear-Resistant And Pressure-Resistant, Suitable Range Is Also Very Wide, In Addition To The General Home Can Be Used, Industrial Manufacturing Can Also Use It To Achieve Anti-Skid Effect, So That The Working Environment Is More Secure, One Of The Necessary Anti-Skid Pad Products.