Ball Mill Rubber Liner ( SAG Mill , AG Mill ) Produced By Hebei Fengmang Technology Co.,Ltd Is Widely Used In Mining, Conveying Of Non-Ferrous Metals And Ferrous Metals, Tailings Engineering, And Providing Wear-Resistant Rubber Parts For Coal Mines And Power Plants. Rubber Lining Has Gradually Replaced The Traditional Cast Steel Lining And Won The Positive Evaluation Of Users.

After Long-Term Research And Development, Design And Test, Our Company Has Successfully Invented Rubber Lining, Composite Lining And Rubber Drum Screen In Ball Mills, SAG Mills And AG Mills, And Has Made Significant Technological Breakthroughs And Innovations. China CITIC Heavy Industries And Other Large State-Owned Enterprises Have a Long-Term Strategic Partnership.

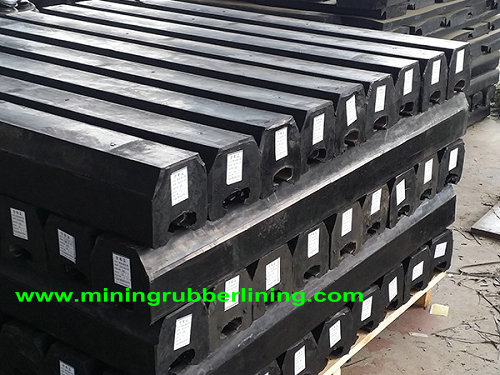

Mill Rubber Lifter Is Made Of Wear-Resistant Rubber, Which Has Been Proven By Decades Of Mine Use To Withstand The Continuous Impact Of Mine Materials. They Have a Variety Of Shape Designs And Shapes To Choose From, In Order To Provide a Variety Of Mills With More High-Performance Wear-Resistant Accessories.

According To Our Rubber Lining Design, Rubber Lifter Can Be Easily Replaced Without Affecting The Shell. Our Mill Lifter Design Is Compatible With Most Shell And End Liner Designs.

Performance Characteristics

Most Of The First, Second And Third Stage Ball Mills Use Rubber Mill Liner. In Many Cases, Rubber Parts Are Most Suitable For Wear-Resistant Parts Of AG And SAG Mills.

Hebei FengMang Technology Co.,Ltd Has Provided Complete Rubber Linings For Some Large Steel Ball Factories Of CITIC Heavy Industries In China And Other Countries. We Provide Rubber Linings For More Than 100 Mines Worldwide.

1, High Wear Resistance And 1.5 Times Longer Service Life Than Metal

2, 8-10 DB Lower Than Metal Noise

3, Light Weight, Easy To Install And Disassemble (It Takes Only 1/3 Of The Time To Install Or Disassemble Metal Bushing)

4, High Cost Performance Ratio

Mill Rubber Liner For Ball Mill, AG Mill, SAG Mill Including Of Rubber Discharge End , Rubber Discharge Cone , Rubber Lifter Bar, Rubber Gate Plate , Rubber Feed Element , Rubber Comer Segment , Rubber Shell Liner , Rubber Shell Plate , Rubber Feed End , Rubber Shell Lifter Bar , Rubber Fill Ring , Rubber Pulp Lifter , Rubber Rubber Frame , Rubber Lid Plugs , Rubber Disc Circle , Rubber Center Circle , Rubber Gate Plug

Mill Rubber Liner Is Used To Protect The Cylinder From The Direct Impact And Friction Of The Grinding Body And Materials. At The Same Time, Different Forms Of Linings Can Be Used To Adjust The Moving State Of The Grinding Body To Enhance The Grinding Effect Of The Grinding Body On The Material, Which Is Helpful To Improve The Grinding Efficiency Of The Mill, Increase The Output And Reduce The Metal Consumption.

Ball Mill Rubber Linings Metal Materials In China Have Been Gradually Replaced By High Wear Resistant Rubber Linings, But With The Continuous Application Of Wear Resistant Rubber Linings In Ball Mill Linings, Metal Linings Have Been Gradually Replaced As The Mainstream Of Market Development.

In Addition To Protecting The Cylinder, The Cylinder Rubber Liner Also Has An Effect On The Movement Law Of The Grinding Body. In Order To Meet The Requirements Of Various Working States (Crushing Or Fine Grinding), The Material Of The Shape Of The Rubber Liner Is Also Different. When The Grinding Is The Main, The Lining Should Have a Strong Pushing Ability To The Grinding Body, And At The Same Time, The Lining Should Have Good Impact Resistance. When The Grinding Is The Main, The Protruding Of The Rubber Liner Is Relatively Small, The Pushing Effect On The Grinding Body Is Weak, The Impact Is Small, And The Grinding Effect Is Strong. The Rubber Liner Is Required To Have Good Wear Resistance.

Contact: Sales Department

Phone: +86 138 10365943

Tel: +86 166 33372827

Email: sales@miningrubberlining.com

Add: No.910 Zhongshan West Road Qiaoxi District Shijiazhuang Hebei China