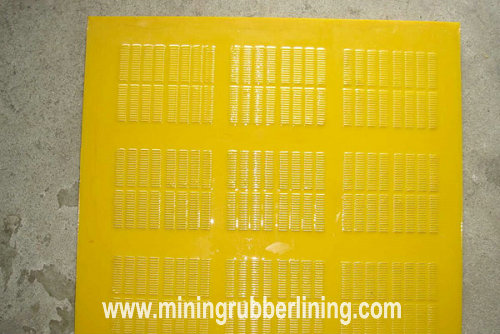

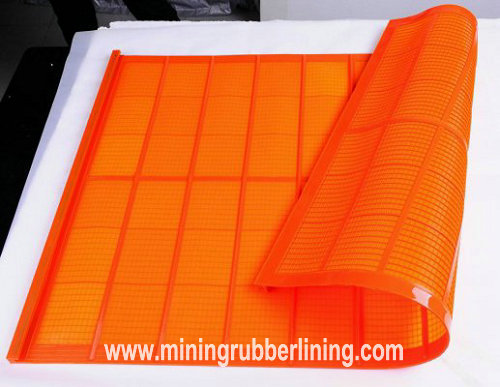

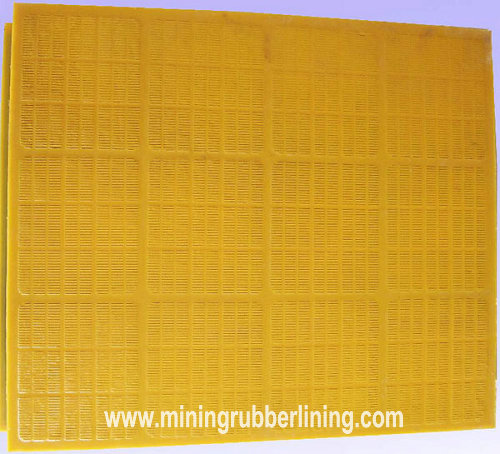

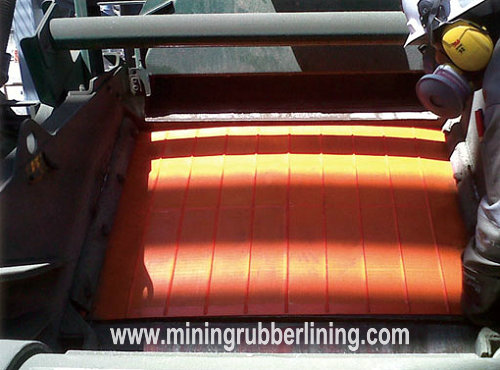

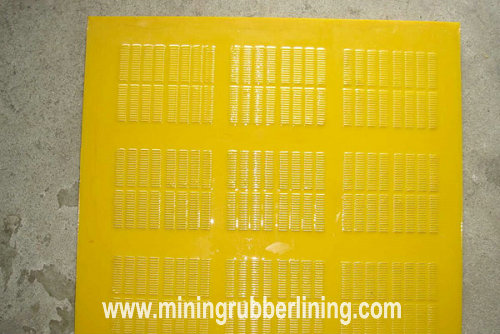

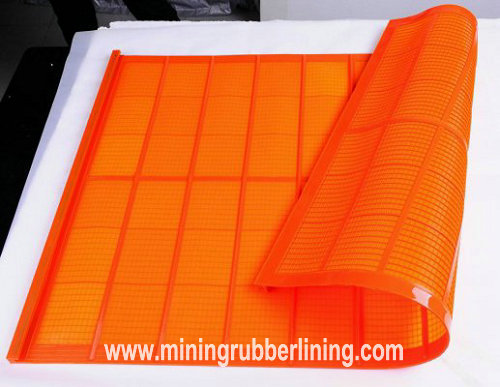

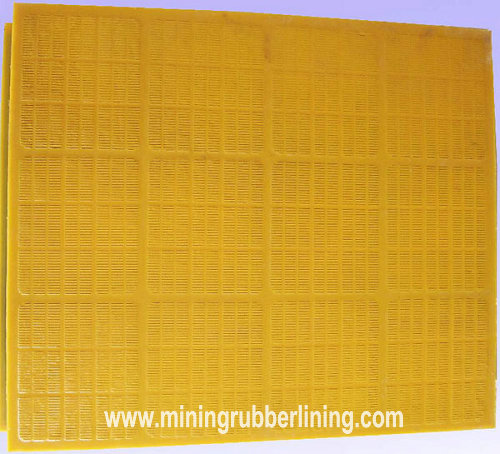

Polyurethane Wire Mesh Also Named PU Wire Mesh Or Urethane Wire Mesh . It Belongs To Mining Equipment, Used In Mining And Quarrying Plants Combined With Vibrating Screen And Other Mining Equipment.

Classification: Polyurethane Square Hole Wire Mesh And Polyurethane Slit Wire Mesh

Source Of Preparation: Polymer Compounds Formed By The Action Of Binary Or Polyisocyanate With Binary Or Polyhydroxyl Compounds.

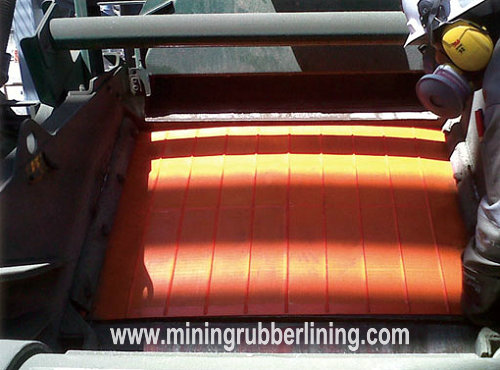

There Are Four Types Of Structure:

1) Mosaic

2) Bolt Connection

3) Pressure Bar Connection

4) Screen Hook Connection

Polyurethane Steel Wire Mesh( Wrapped Wire-Welded Core Wire Welded Mesh Support Net) The Material Has Beautiful Appearance, Bright Color, Light Weight, High Mechanical Strength, Heat Insulation, Sound Insulation, Corrosion Resistance, Excellent Weather Resistance, No Secondary Decoration, Various Colors.

1. Tensile Strength, High Tear Resistance, Good Wear Resistance, Good Resilience, Small Compression Permanent Deformation, Long Service Life.

2. Has Strong Binding Force With Metal Matrix And Is Not Easy To Layer And Remove

3. High Surface Finish And Stable Size.

High Strength Polyurethane Composite Wire Mesh, Which Belongs To The Technical Field Of Screening Equipment, Is Used To Solve The Problem Of Low Strength And Short Service Life Of Ordinary Wire Mesh. The Utility Model Comprises An Internet Connection And a Supporting Net, The Improvement Of Which Is That The Internet Connection Is a Wire Mesh, The Supporting Net Is a Polyurethane Supporting Net, The Polyurethane Supporting Net Is Located Under The Wire Mesh, And It Is a Lattice Of Crosswise Intersecting Sides, And Its Warp And Weft Strips Are All Made Of Wire Rope Core And Polyurethane Surface Layer.

The Above Improvements Endow The Utility Model With Excellent Properties Different From Ordinary Metal Wire Mesh. And It Has High Strength, Stiffness And Bearing Capacity, And Can Effectively Reduce Vibration Noise And Improve Wire Mesh Service Life. The Utility Model Can Be Made Into a Screening Device Of Various Shapes, Especially a High Frequency Vibrating Screen Suitable For Electromagnetic Excitation. It Can Be Widely Used In Screening, Filtration, Dehydration, Desliming And Other Operations In Many Industries.

8 Mmx5mm 1.2 m x5 m

8 Mmx12mm 1.5 m x5 m

8 Mmx20mm 2 m x5 m

Polyurethane Wire Mesh Suitable For Metallurgical, Coal, Chemical, Construction And Many Other Sectors Of Vibrating Screen, As Bulk Materials Fine-Grained Sieve, Dry Screen Can Be. Can Also Be Used For Classification Of Certain Corrosive Materials.

Advantages Of Polyurethane Wire Mesh

1. Long Service Life And Large Bearing Capacity. Because Polyurethane Elastic Wire Mesh Uses Wire Rope As Skeleton Material, Plus Polyurethane Itself Has Very High Elastic Modulus, High Strength Absorption Impact Force, High Wear Resistance, So It Has a Very High Tensile Strength, Its Bearing Capacity Is More Than 2.5 Times That Of Rubber Wire Mesh. Its Service Life Is 8-10 Times Higher Than That Of Ordinary Metal Wire Mesh ,3 Times Higher Than That Of Stainless Steel Screen Surface ,3.9 Times Higher Than That Of Natural Rubber, And Is The Best Screen Surface Material With Wear Resistance In The World. Polyurethane Wire Mesh Production Materials Belong To Polymer Organic Elastomer, With Wear Resistance, Flexural Flexibility, Bearing Capacity. After Special Treatment, The Raw Materials For The Production Of Polyurethane Wire Mesh Ensure That They Are Never Delaminated Under Long-Term Alternating Load.

2. Screening Efficiency Is High. The Inner Self-Cleaning Property Of The Screen Surface, No Hole Plugging, High Screening Efficiency. Because Of The Strong Water Permeability Of Polyurethane And The Large Cone Angle Of Sieve Hole (140°), It Can Effectively Prevent The Adhesion Of Wet Fine Particles, So It Is Suitable For Screening And Grading Of Wet Fine Particles. i Plant Polyurethane Wire Mesh Using Imported Raw Materials, Its Elastomer And Its Own Good Tensile Properties, In Dynamic Conditions To Effectively Avoid Plugging Phenomenon.

3. Wide Scope Of Application, Professional Applicability Is Stronger, Applicable To Any Type Of Vibrating Screen Machine And Machine Production. Polyurethane Wire Mesh Is Used In Hydropower Station, Building Materials And Other Metal Mining Industry. 0.1 Mm—170mm Screening Of All Materials In The Range, Whether Dry Or Wet, Does Not Affect Screening Efficiency. Dehydration, Deintercalation, And More Fully Show The Superiority Of Polyurethane Sieve Surface In The Range Of 0.5 m—3mm. Product Water Resistance, Corrosion Resistance, Aging Resistance, Easy To Replace And Maintain. Polyurethane Density Is Small (1.32 Kg/m 3), The Weight Is Lighter Than The Metal Screen Surface, It Can Reduce The Production Unit Consumption, So It Can Meet The Requirements Of Large-Scale Development Of Sieve Machine.

High Accuracy Of 4. Screening. Polyurethane Wire Mesh Production Process Using Mold Pouring Molding Process, Accurate Pore Size, High Screening Quality, The Particle Size Of Materials Under The Sieve Can Well Meet The Requirements Of Users. Simple Installation, Easy To Replace And Repair, This Product Is Suitable For Any Type Of Screening Machine, Light Weight, For On-Site Installation Or Replacement Maintenance, Greatly Reduced The Workload.

5. Working Noise Is Low And Meets The Environmental Noise Standard Of National Specifications. According To The Actual Measurement, The Same Sieve Machine Uses Polyurethane Wire Mesh Than Metal Wire Mesh Can Reduce The Noise By 5 To 20 Decibels, And Greatly Reduce The Dust Flying, So That The Production Site Has a Quiet And Clean Working Environment.

6. Significant Economic Benefits. Although The Price Of Polyurethane Rubber Screen Surface Is Higher Than That Of Metal Wire Mesh, If The Factors Of Screening Efficiency, Maintenance Cost And Service Life Are Considered Synthetically, It Will Be Found That The Overall Benefit Of Polyurethane Screen Surface Is Much Better Than That Of Ordinary Metal Screen Surface. According To The Investigation ,45 Tons Of Steel Can Be Saved For Each Ton Of Polyurethane Rubber Wire Mesh Used. Save Maintenance Cost 40,000 Yuan. Therefore, Replacing Steel Sieve Surface With Polyurethane Sieve Surface Will Be An Inevitable Choice For Most Enterprises In The Future.