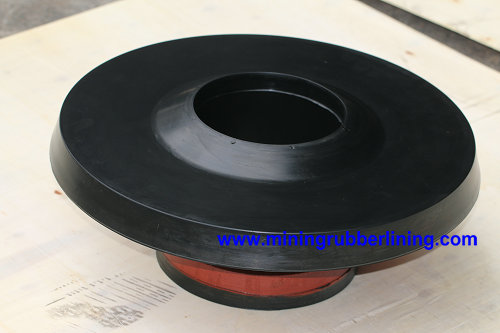

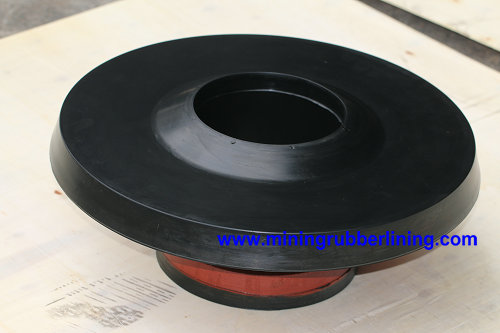

Rubber Impeller ( Rubber Lined Impeller Or Rubber Coated Impellers ) Refers Not Only To The Wheel With Moving Blade, But Also To The Rotor Of Impulsive Steam Turbine.Rubber Impeller Can Be Classified According To Shape And Opening And Closing.

Definition

GB/T7021-1986 Terms For Rubber Centrifugal Pumps

Impellers

A Rotating Body With A Blade —— Which Transmits Energy To A Liquid.

HG/T3186-1987 Terms For Rubber Chemical Centrifugal Compressors

Impellers

Centrifugal Compressor Rubber Impeller —— Is a Concentrated Work Component, Which Consists Of Blade, Wheel Disc, Wheel Cover And Other Parts; Gas In Its Channel To Obtain Energy.

GB/T3858-1993 Terms For Rubber Hydraulic Transmission

Impellers

Hydraulic Coupling Rubber Impeller —— a Working Wheel With One Or More Rows Of Blades. Separate Core Rubber Impeller, Concentric Rubber Impeller, Axial Flow Rubber Impeller.

Axial Compressor Rubber Impeller —— a Combination Of Moving Cascade And Wheel Disc, Which Is The Main Part Of The Rotor. It Is a Component In An Axial Flow Compressor That Transfers Energy Directly To The Gas.

HG/T3160-1987 Rubber Stirring Equipment Terminology

Impellers

Agitating Equipment Rubber Impeller—— Current Use, Agitators. No Longer Use Rubber Impeller, Stirring Wheel.

Classification Of Rubber Impeller

The Rubber Impeller Of Centrifugal Pump Has Four Main Forms :(a) Closed ;(b) Front Half Open ;(c) Rear Half Open ;(d) Open

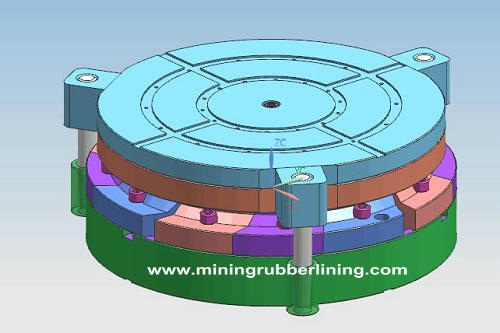

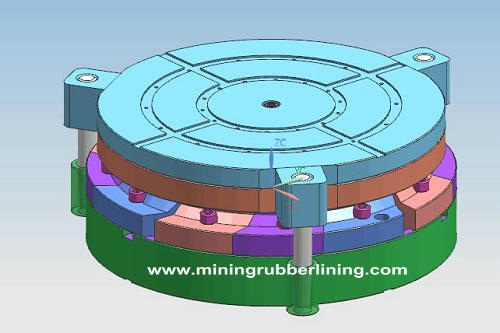

1- Rubber Impeller ;2- Rear Cover Plate ;3- Hub ;4- Front Cover Plate ;5- Rubber Impeller Seal Ring ;6- Stiffeners

Closed Rubber Impeller

Consists Of Blades And Front And Rear Cover Plates. The Efficiency Of Closed Rubber Impeller Is High, And The Manufacturing Difficulty Is Great, So It Is Most Used In Centrifugal Pump. Suitable For Conveying Clean Liquid With Low Viscosity Such As Clear Water And Solution.

Semi Open Rubber Impeller

There Are Generally Two Kinds Of Structures: One Is The Front Half Open Type, Which Is Composed Of The Rear Cover Plate And The Blade. The Rubber Impeller Has Low Efficiency. The Other Is The Rear Half Open Type, Which Is Composed Of The Front Cover Plate And The Blade. The Semi-Open Rubber Impeller Is Suitable For Conveying Liquid Containing Suspended Solids Such As Solid Particles And Fibers. The Semi-Open Rubber Impeller Is Difficult To Manufacture, Low Cost And Strong Adaptability. It Is Used In Centrifugal Pump For Refining Chemical Industry And Is Used To Transport Clear Water And Liquid Similar To Clear Water.

Open Rubber Impeller

Only Blade And Blade Reinforcement Bars, No Front And Rear Cover Plate Rubber Impeller (Open Rubber Impeller Blade Number Less Than 2-5 Pieces).The Rubber Impeller Has Low Efficiency And Less Application, Which Is Mainly Used To Transport Liquid With High Viscosity And Slurry Liquid.

The Blade Of Rubber Impeller Of Centrifugal Pump Is Generally Back Curved Blade. There Are Two Kinds Of Blades, Cylindrical And Twisted, The Application Of Twisted Blades Can Reduce The Load Of The Blade, And Can Improve The Suction Performance Of Centrifugal Pump And Improve The Cavitation Resistance, But The Manufacture Is Difficult And The Cost Is High.

Centrifugal Pumps For Refining And Chemical Engineering Require Rubber Impellers To Be Integral Rubber Impellers For Casting Or Full Weld Welding. Welding Rubber Impeller Developed, Mostly Used In Casting Poor Performance Of Metal Materials (Such As Iron And Its Alloys) Made Of Chemical Special Centrifugal Pumps. The Geometric Accuracy And Surface Finish Of Welded Rubber Impeller Are Better Than That Of Cast Rubber Impeller, Which Is Beneficial To Improve The Efficiency Of Centrifugal Pump.

Shape

Centrifugal Rubber Impeller

The Blade Shape Of Rubber Impeller Of Centrifugal Fan Has Veneer Type, Arc Type And Wing Type. The Wing Blade Has Good Aerodynamic Characteristics, High Efficiency, Good Strength And High Stiffness. The Disadvantage Is That The Manufacturing Process Is Complex, And When Conveying The Gas With High Dust Concentration, The Blade Is Easy To Wear, And After The Blade Is Worn Through, The Impurity Enters The Inside Of The Blade, Which Makes The Rubber Impeller Out Of Balance And Produces Vibration. The Plate Straight Blade Is Simple To Manufacture, But The Flow Characteristics Are Poor, While The Efficiency Of The Plate Curve Backward Blade Is Quite Close To That Of The Other Working Point Except That The Efficiency Near The Highest Efficiency Point Is Lower Than That Of The Airfoil.

Forward Rubber Impeller

The Forward Rubber Impeller Generally Adopts The Arc Type Blade, In The Backward Rubber Impeller, The Large Fan Mostly Uses The Airfoil Blade, For The Coal-Fired Boiler Induced Fan With Low Dust Removal Efficiency May Adopt The Arc Type Or The Flat Plate Type Blade. There Are More Centrifugal Fans With Flat Blade.

Plate Blade ;(b) Narrow Arc Blade ;(c) Arc Blade ;(d) Airfoil ;(e) Backward Blade With Plate Curve

Compressed Rubber Impeller

Also Called Work Wheel.The Only Element In a Centrifugal Compressor That Works On Airflow.The Most Major Component On The Rotor. Generally Consists Of Wheel Disc, Wheel Cover And Blade And Other Parts. Under The Action Of The Rubber Impeller Blade, The Gas Rotates At High Speed With The Rubber Impeller, And The Gas Is Subjected To The Action Of Rotating Centrifugal Force, As Well As The Expansion Flow In The Rubber Impeller, Which Makes It Increase The Pressure After Passing Through The Rubber Impeller.

Requirements For Rubber Impellers

(1) Can Give a Large Energy Head ;(2) Gas Flow Through The Rubber Impeller Loss Is Small, That Is, Gas Flow Through The Rubber Impeller Efficiency Is High ;(3) Gas Flow Out Of The Rubber Impeller Parameters Are Appropriate, So That The Gas Flow Through The Rear Fixed Element Loss Is Small ;(4) Rubber Impeller Type Can Make The Stage Or The Whole Machine Performance Curve Stable Working Condition Zone And High Efficiency Zone Wide. Often Divided Into Closed, Semi-Open And Open Rubber Impellers.

In Wind Turbines, Rubber Impellers Consist Of Wheels And Blades. The Wind Passes Through The Rubber Impeller And Drives The Rubber Impeller To Rotate, Thus Driving The Generator To Rotate And Converting The Wind Energy Into Electric Energy. At This Time, The Rubber Impeller Is Required To Have a Large Enough Windward Surface When Rotating To Extract Enough Energy From The Wind; At The Same Time, When The Wind Speed Is Too Large, It Should Be Able To Automatically Adjust The Windward Angle Of The Blade To Avoid Damage To The Machinery Due To Excessive Force.

Common Material For Rubber Impeller

Cast Iron, Bronze, Stainless Steel, Manganese Bronze, Monel Alloy, Inconel, And Nonmetallic Materials.

Non-Metallic Materials

Pps Plastics, Phenolic Resins, Etc.

Wear Prevention

The Wear Of The Rubber Impeller Of The Fan Is Related To The Composition, Particle Size, Concentration, Shape, Impact Speed, Impact Angle, Chemical Composition, Properties, Temperature And Humidity Of The Abrasive. And The Inhomogeneity Of Gas Flow Inside The Rubber Impeller Accelerates The Wear. As a Measure To Prevent The Wear Of Rubber Impeller: First, Reduce The Dust And Corrosive Gas Entering The Fan, So It Is Necessary To Reform The Fan Operation System; Second, Try To Make The Local Wear Tend To Uniform Wear, Which Needs To Improve The Wear Resistance Of Rubber Impeller. If The Wear Resistance Of Rubber Impeller Is Improved, High Hardness And Good Wear Resistance Materials Can Be Used. This Will Not Only Bring Difficulties To The Rubber Impeller Manufacturing Process, But Also Unreasonable From An Economic Point Of View. Therefore, It Is An Economical And Reasonable Solution To Improve The Surface Quality Of The Rubber Impeller Of The Fan.

Coating Antiwear Paint

The Main Anti-Wear Coatings Are Resin Anti-Corrosion Wear-Resistant Coatings, Rubber Anti-Corrosion Wear-Resistant Coatings, Quartz Water Glass And Ceramic Anti-Corrosion Wear-Resistant Materials.

890 Wear Resistant Compound Is a Ceramic Composite Used To Repair And Protect Worn Metal Surfaces, Which Has Better Wear Resistance And Adhesion To The Base Metal. But 890 Wear Resistant Compound Coating Thickness Must Be Up To 6 Mm Or a Little Thicker, Which Is Not Suitable For Some Narrow Channels Or More Strict Starting Requirements Of The Rotor. Similarly, Adding a Layer Of Wear Resistant Liner On The Blade To Solve The Fan Rubber Impeller Wear Also Has Such Problems.

Blade Surface Surfacing

Surface Surfacing Welding Is To Select a Certain Surfacing Welding Rod (Or Wire), Manual Arc (Or Automatic Welding) Surfacing Welding In The Blade Prone To Wear, To Improve The Surface Quality Of The Blade To Protect The Blade And Improve The Blade Life. D217、D237、D317B、D707 And D717 Are Generally Used In Blade Surfacing Welding Strips. D217 And D237 Surfacing Welding Metals Belong To Horse Body Steel And Have Certain Wear Resistance, But The Tendency Of Surfacing Welding Cracks Is Large. D317B Surfacing Material Is a Kind Of Surfacing Alloy Composed Of a Large Number Of Tungsten Carbide (Wc) Particles Distributed On The Metal Matrix. Because Of The High Melting Point And Hardness Of The Wc, The Metal Hardness Of The Welding Pass Is Also Very High And The Impact Resistance, The Hardness Hrc≥60, And The Tendency Of The Surfacing Metal Crack Is Small.

Surface Spray Welding (Spray)

Spray Welding Process Is The Process Of Spraying And Melting The Self-Melting Alloy Powder On The Workpiece Surface With Heat Source And Making It Form a Dense Spray Welding Layer. Each Spray Welding Wear Resistant Powder Is Basically Using Ni-Cr-B-Si Series Of Nickel Base Spray Welding Powder. The Basic Microstructure Of Their Spray-Welding Layer Is Ni-Cr-Fe Solid Solution, While There Are a Large Number Of Boron Compounds And Tungsten Carbide. These Wc Particles Are Uniformly Distributed In The Ni Base Spray Layer. These Particles Are Uniform And Discontinuous, But Can Form a Skeleton With Hardness Up To Hrc70. Ni Base Material Is Filled In The Skeleton And Can Withstand High Abrasive Wear When Subjected To Abrasive Erosion. The Surface Hardness Of Spray Welding Is Hrc55~70 And Its Basic Composition Is Ni60%Hrc55~Wc35%..

Anti Corrosion Measures

The Corrosion And Wear Of The Rubber Impeller Of Fan Is Mainly Caused By Corrosion And Stress Corrosion Caused By Corrosive Gas In The Conveying Medium Of Fan. The Types Of Corrosion Caused By Different Conveying Media Are Also Different. In Order To Prevent Corrosion And Wear Of Rubber Impeller, The Following Measures Are Usually Adopted: Stainless Steel With Strong Corrosion Resistance Is Used As Rubber Impeller Material; Anticorrosive Coating Is Coated Or Sprayed On The Surface Of Rubber Impeller And The Surface Quality Of Rubber Impeller Is Improved To Solve The Problem Of Corrosion Wear.

Corrosion Resistant Wear Materials

Austenitic Stainless Steel (e.g .1 Cr18Ni9Ti) Has Low Yield Strength And Is Not Suitable For Making Rubber Impeller With High Rotational Speed, Which Is Suitable For Anticorrosion Rubber Impeller Material As a General Low Speed Fan. Cr13 Kinds Of Stainless Steel Are Mainly Used When Containing Medium With Corrosive Gas And Smoke Such As Co2, But Stress Corrosion Should Be Paid Attention To, While Fan Rubber Impeller With High Corrosion Resistance And High Rotational Speed Is Widely Used Martensitic Precipitated Stainless Steel, Such As 0 Cr17Ni4Cu4Nb And Fv520B.

Coating Of Corrosion Resistant Layer Of Rubber Impeller

Amorphous Nickel-Phosphorus (Ni-P) Alloy Is a Successful Surface Coating Method. The Grain Boundary Corrosion And Grain Boundary Defects Are Avoided Due To The Ideal Amorphous Structure And Alloy Characteristics Of The Coating. The Ni-P Alloy Coating With Hardness Of Hrc50~70 Has Strong Corrosion Resistance, Wear Resistance And Corrosion Resistance To Hydrochloric Acid, Sulfuric Acid, Phosphoric Acid And Caustic Soda.

An Amorphous Nickel-Phosphorus (Ni-P) Alloy Coated On The Surface Of The Rubber Impeller Of The Fan Is a Good Corrosion Resistance Method.

Spraying Of Corrosion Resistant Layer On Rubber Impeller

The Corrosion Resistance Spraying Of Rubber Impeller Of Fan Has Surface Thermal Spraying And Plasma Spraying. Spraying Materials Are Nickel And Nickel Alloy Wire, Powder; Stainless Steel Wire, Powder, Etc. Nickel And Nickel Alloy Spray Coating Has Good Corrosion Resistance To Medium Such As Hydrogen Sulfuric Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrofluoric Acid, Acetic Acid, Ferrous Sulfate Solution And Dry Gas, But Not To Hydrochloric Acid, Nitric Acid, Potassium Acetate, Sulfite And So On.

Austenitic Stainless Steel In Stainless Steel Is Used For Thermal Spraying More, Such As 1 Cr18Ni9Ti, Has Good Processability And Good Corrosion Resistance In Most Oxidizing And Some Reducing Media.

There Are Other Methods For Corrosion Resistance Of Fan Rubber Impeller, Such As Rubber Anticorrosive Coating, Epoxy Resin Coating And So On. There Are Many Wear-Resistant And Anti-Corrosion Methods Of Fan Rubber Impeller, Which Are Limited By The Operating Conditions Of Fan And The Manufacturing Technology Of Rubber Impeller.

Auxiliary Rubber Impeller

The So-Called Auxiliary Rubber Impeller Hydrodynamic Seal Refers To The Installation Of An Open Rubber Impeller In The Opposite Direction Coaxially Near The Back Of The Rear Cover Plate Of The Rubber Impeller Of The Pump. When The Pump Works, The Secondary Rubber Impeller Rotates With The Main Shaft Of The Pump, And The Liquid In The Secondary Rubber Impeller Also Rotates Together, And The Rotating Liquid Produces An Outward Centrifugal Force, Which.

On The One Hand, Supports The Liquid Flowing To The Mechanical Seal And Reduces The Pressure At The Mechanical Seal. On The Other Hand, It Prevents The Solid Particles In The Medium From Entering The Friction Pair Of The Mechanical Seal, Reduces The Wear Of The Grinding Block Of The Mechanical Seal, And Prolongs Its Service Life.

In Addition To The Sealing Effect, The Auxiliary Rubber Impeller Can Also Play The Role Of Reducing The Axial Force. In The Submersible Sewage Pump, The Axial Force Is Mainly Composed Of The Pressure Difference Force Of The Liquid Acting On The Rubber Impeller And The Gravity Of The Whole Rotating Part.

The Action Direction Of The Two Forces Is The Same, And The Resultant Force Is Composed Of Two Forces. It Can Be Seen That The Axial Force Of The Submersible Sewage Pump Is Larger Than That Of The General Horizontal Pump Under The Condition That The Performance Parameters Are Exactly The Same, And The Balance Difficulty Is More Difficult Than That Of The Vertical Pump. So In The Submersible Sewage Pump, The Bearing Is Easy To Damage Its Reason Also Has The Very Big Relation With The Axial Force.

And If The Secondary Rubber Impeller Is Installed, The Direction Of The Pressure Difference Force Acting On The Secondary Rubber Impeller By Liquid Is Opposite To The Resultant Force Of The Above Two Forces, Which Can Counteract Part Of The Axial Force, Which Also Plays The Role Of Prolonging The Bearing Life.

But The Use Of Secondary Rubber Impeller Sealing System Also Has a Disadvantage, That Is, In The Secondary Rubber Impeller To Consume a Part Of Energy, Generally Around 3%, But As Long As The Design Is Reasonable, It Can Completely Reduce This Part Of The Loss To The Minimum.